FlexiRip

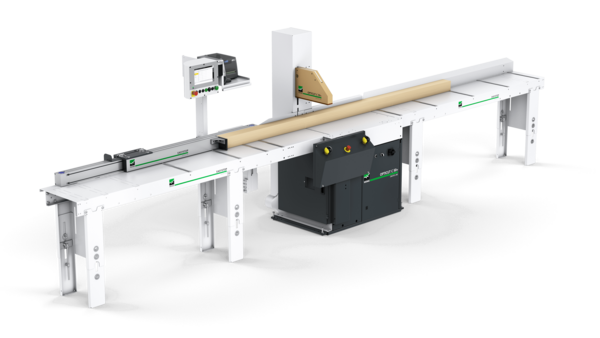

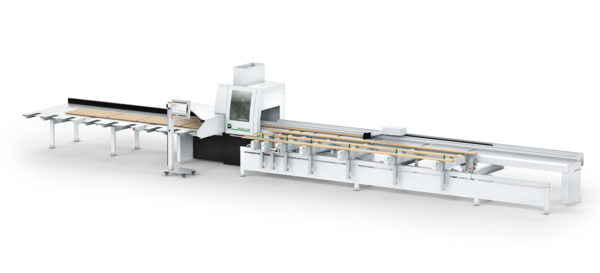

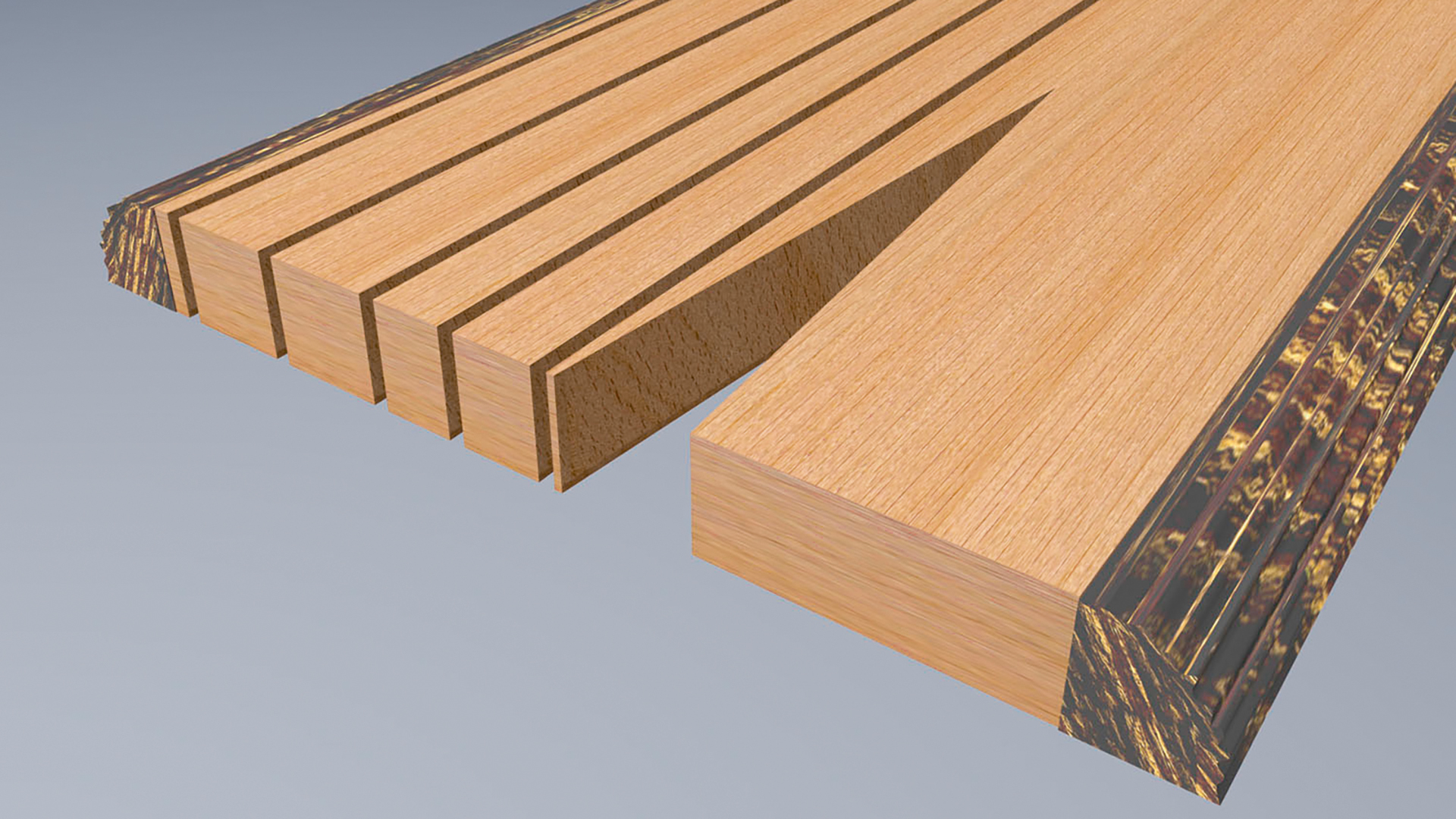

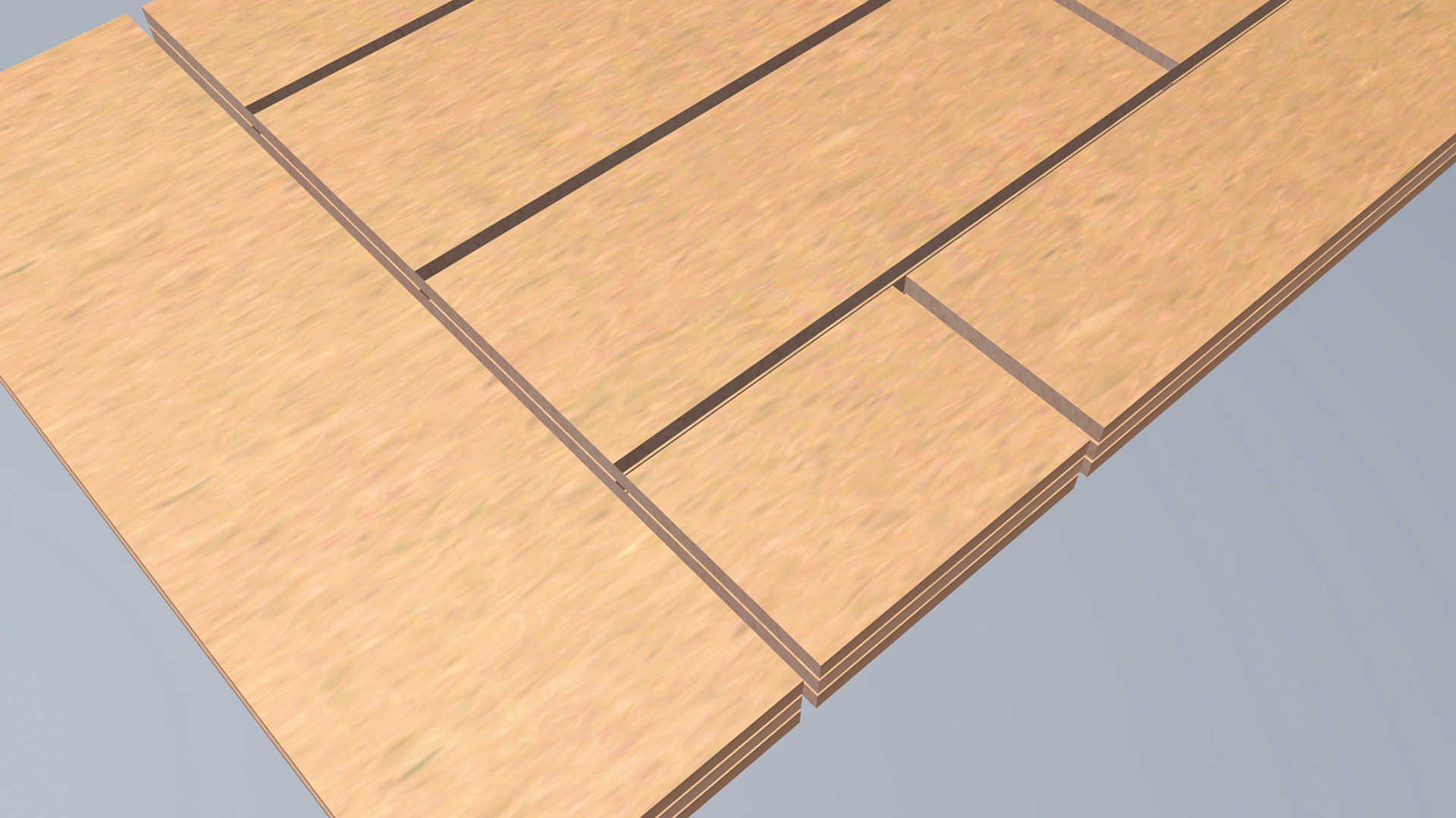

Back to previous pageWhen it comes to cutting planks, boards and panels, the FlexiRip has established a reputation as an efficient and flexible longitudinal circular saw. Customers particularly appreciate the high levels of flexibility, the optimal wood recovery and the one-man operation. In addition to solid wood, a range of other materials can also be cut, including plastic, aluminum and a variety of panel types. The FlexiRip's cut length and usable width is harmonized with its workpiece dimensions. Operation is simple: Lay and align the workpiece on the machine table and initiate cutting via the pedal! When the pedal is released, the saw blade dips and returns to the start position. The cutting feed can be continuously and finely adjusted from 0 – 80m/min.

- High production output, even with extremely hard materials

- High cutting accuracy and optimum material yield

- Quick saw blade change

- High operational safety

- Precise positioning stop

- Can be integrated in cutting systems

6 Universal applications

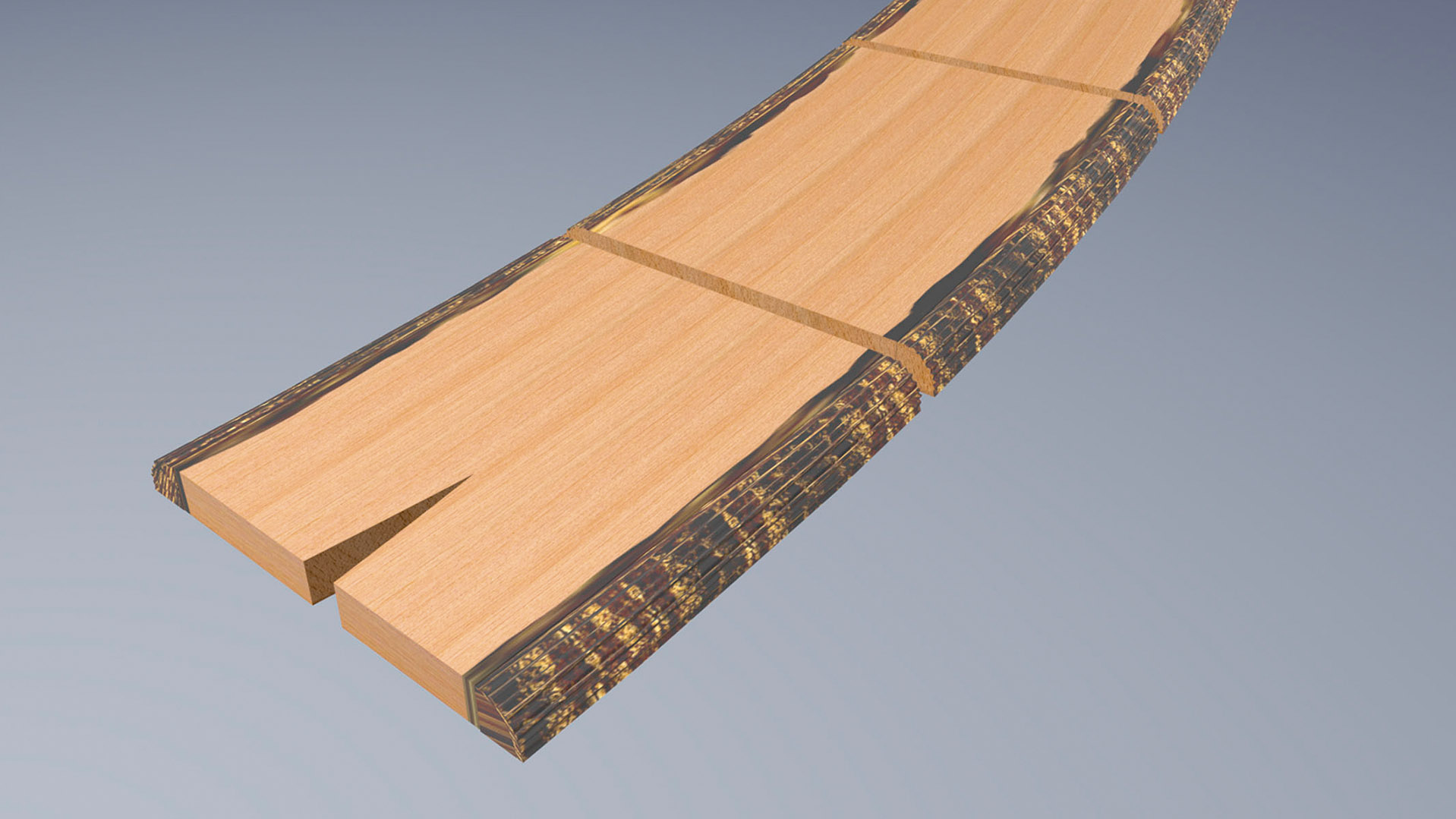

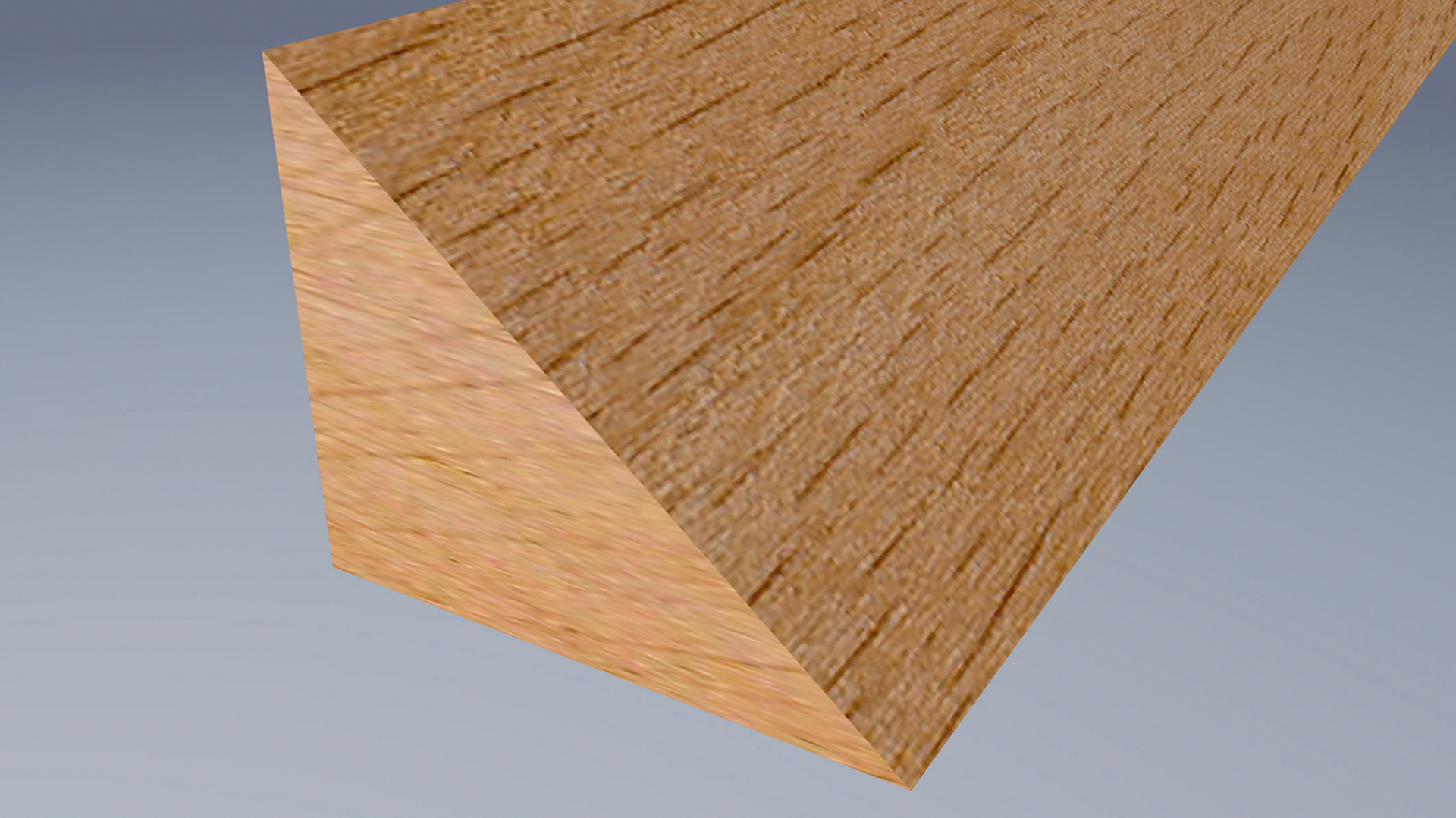

The FlexiRip longitudinal circular saw is the ideal machine for a wide variety of applications: Longitudinal cutting, cross-cutting, diagonal cutting, miter cutting, cross sections and package cutting - all with one machine! With cutting heights up to 210 mm, the FlexiRip offers outstanding flexibility for all operational requirements.

The FlexiRip provides

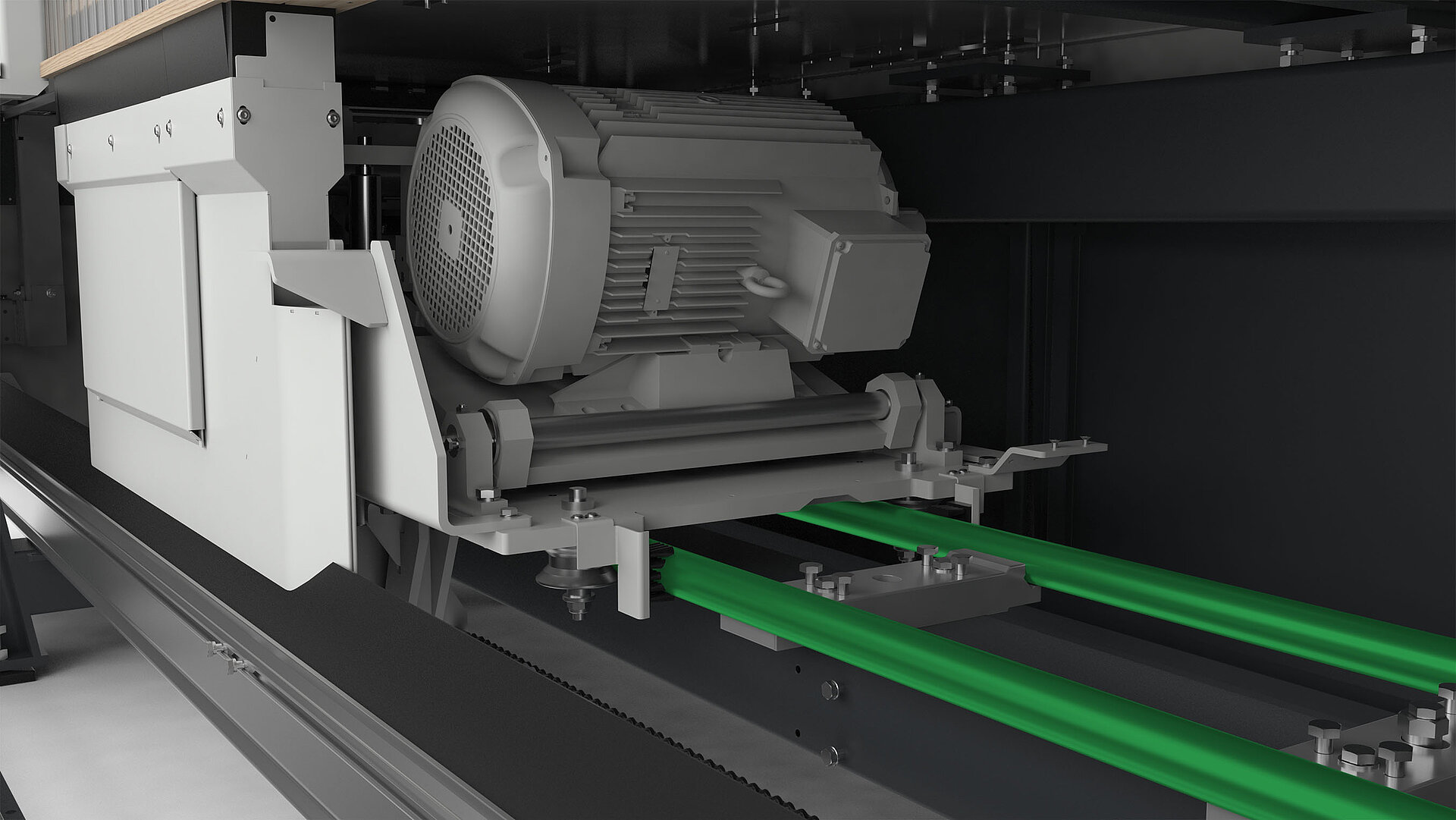

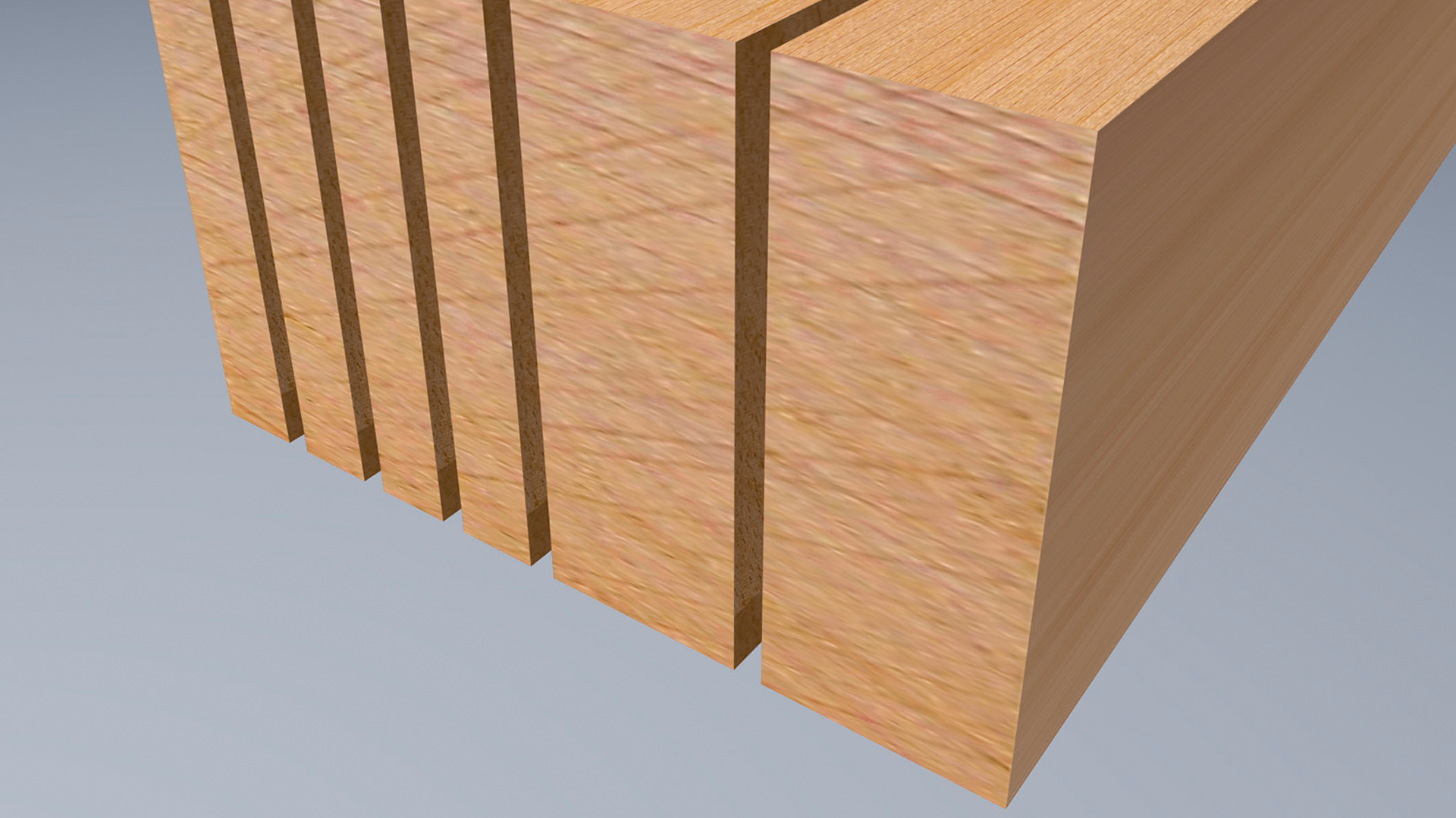

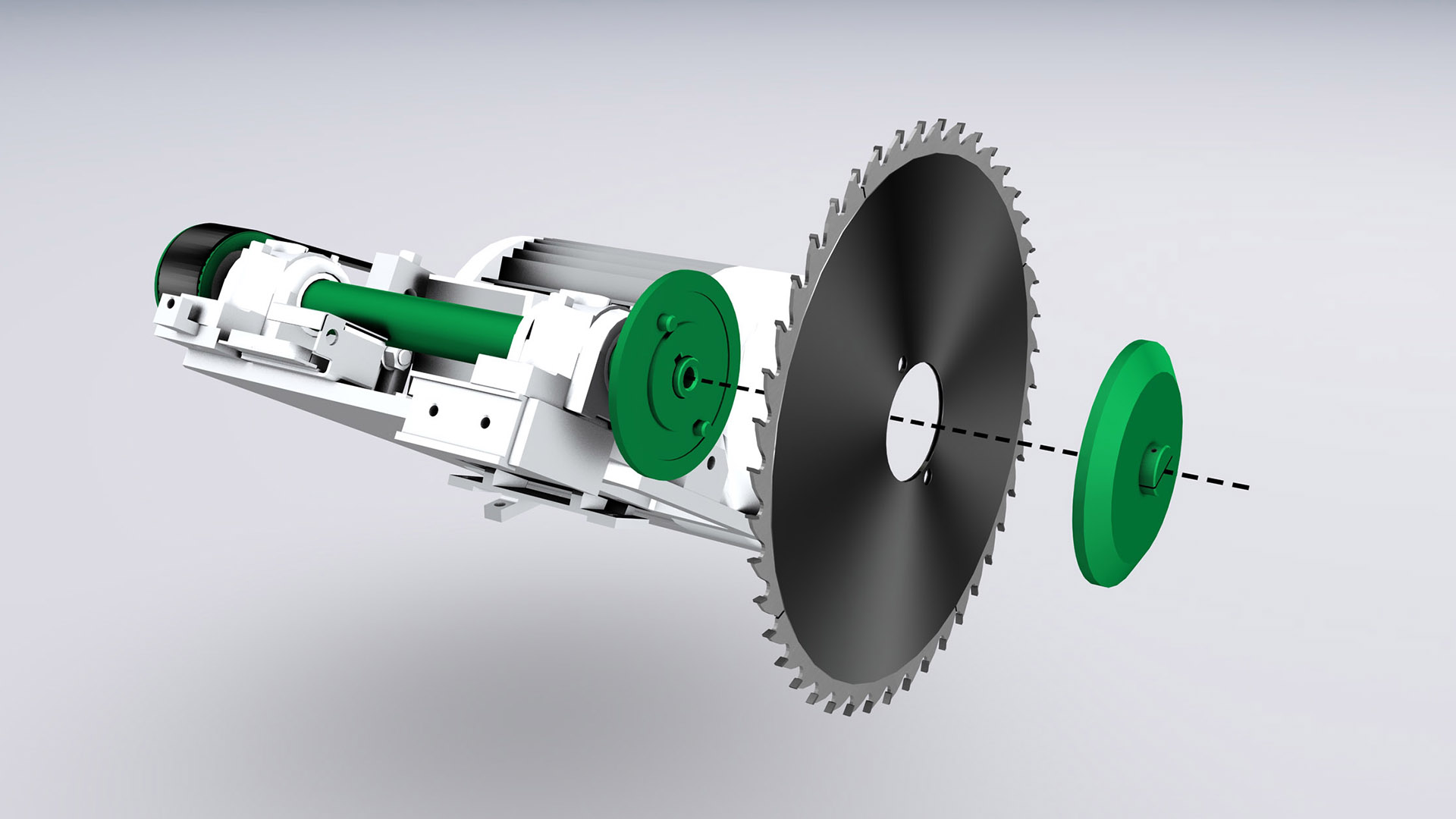

The guide system of the saw carriage is significantly optimized for even better cutting quality: The saw carriage is guided via lateral rollers on wear-free, hardened and polished (saw carriage) tracks. When cutting pressure becomes excessive, the anti-blocking system is automatically activated. This concept ensures play-free action and high cutting precision in the 1/10-mm range. At the same time, optimal safety is also guaranteed.

The machine construction also guarantees high table stability with heavy workpieces up to 600 kg. Even the

standard version enables cut heights up to 210 mm. The 8-mm-thick protective lamellae provide active safety. For quick and easy servicing of the machine, the front machine cladding can be opened and effortlessly lifted via a quick-release catch.

The horizontal placement of the hold-down unit guarantees secure fixing of the workpiece to the machine table, even if it is not lying centrally. In this version (see image), the hold-down unit is equipped with a wooden insert and rubber coating, which guarantees a secure hold even when cutting narrow strips.

On the new large 21.5” operating display, the operator immediately sees all the information that is needed for efficient work. In addition to traditional width cutting, the display offers other functions such as automatic cutting height detection, calculation of resulting dimensions, grooving, and connectivity for the exchange of cutting lists and statistical data. The operating display is permanently mounted at the cutting position; upon request, it can also be mounted to the swivel arm which allows it to be moved.

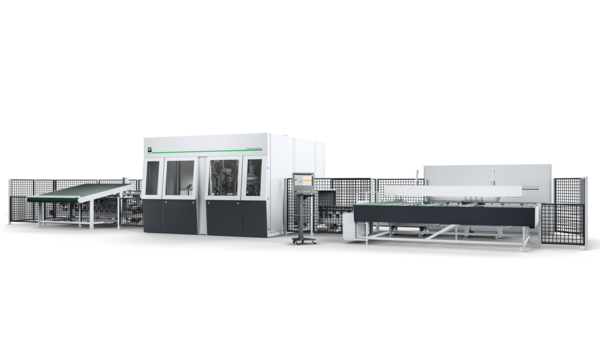

OptiCut C 700 Flexi

The OptiCut C 700 Flexi cross-cut saw makes the FlexiRip a modern cutting line. The result is an efficient one-man solution for cross sections and longitudinal cutting. The OptiCut C 700 Flexi is mounted on guides and can easily be set to the required depth according to the width of the workpiece. This concept creates efficiency as well as significant savings on space.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/d/csm_Header_Holz-Handwerk_2023_a6ad700671.jpg)