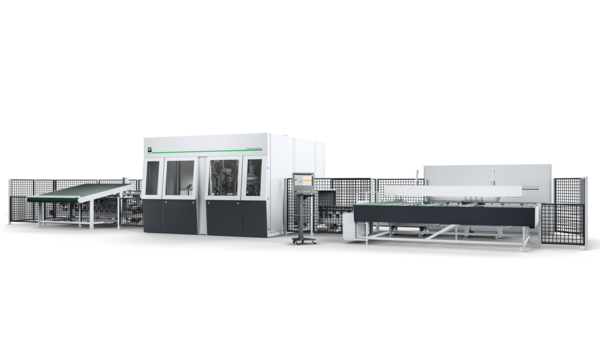

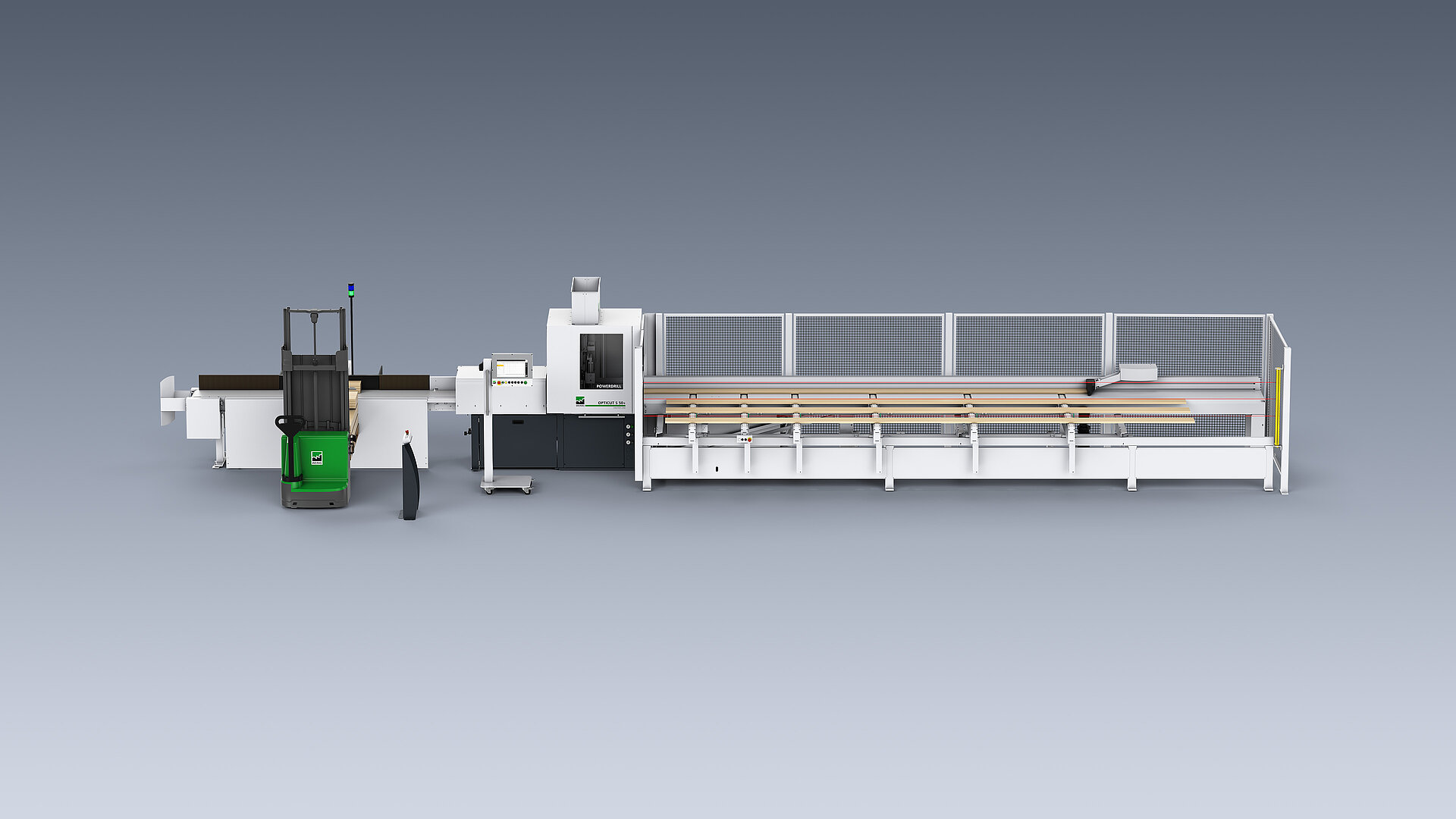

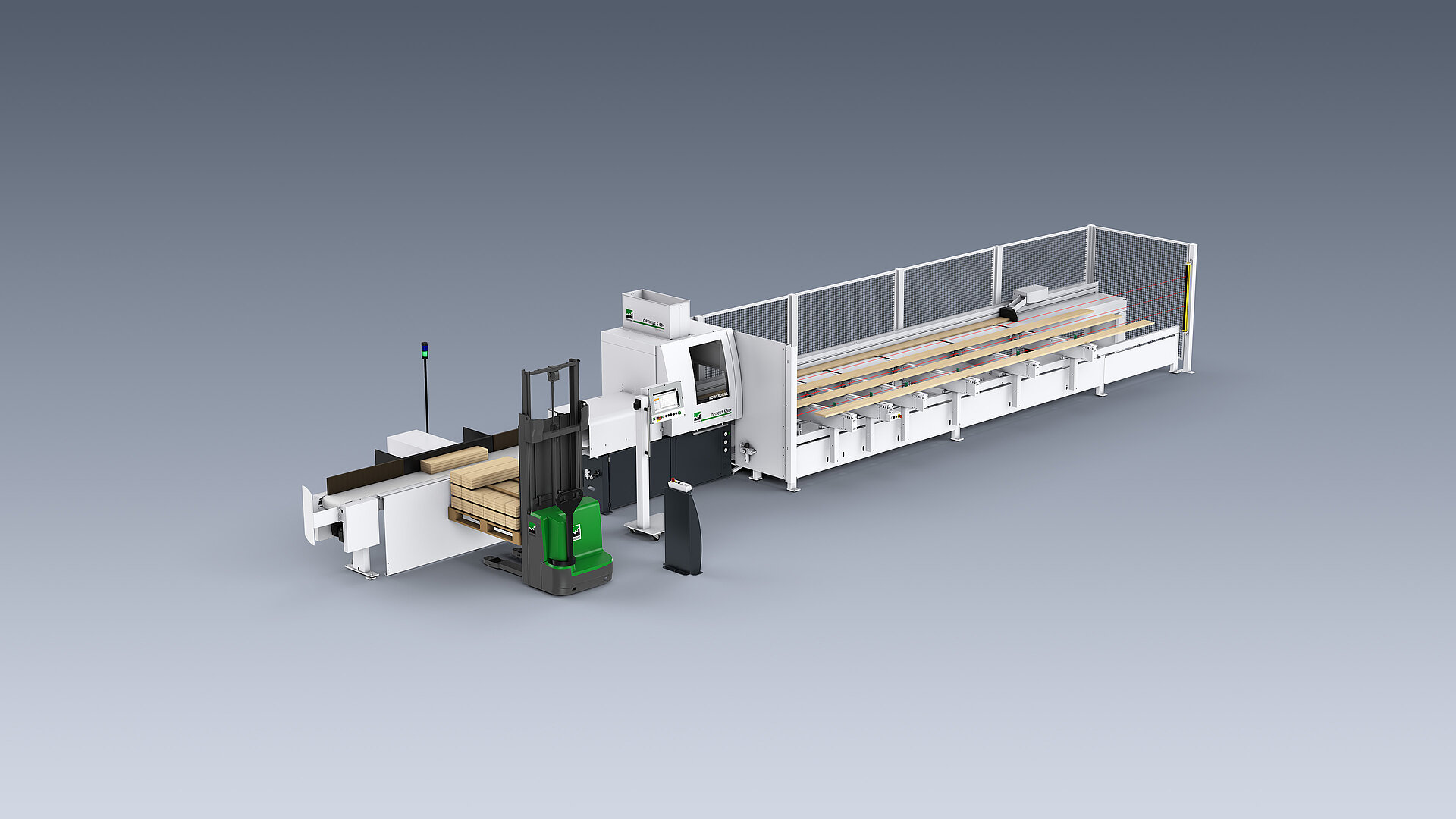

OptiCut S 50+ Powerdrill

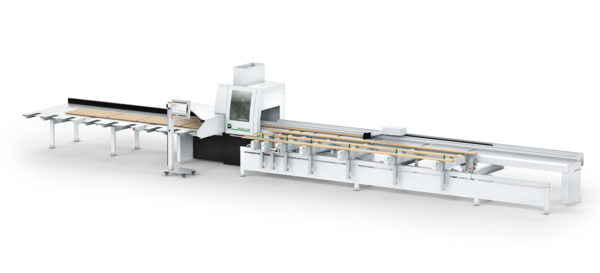

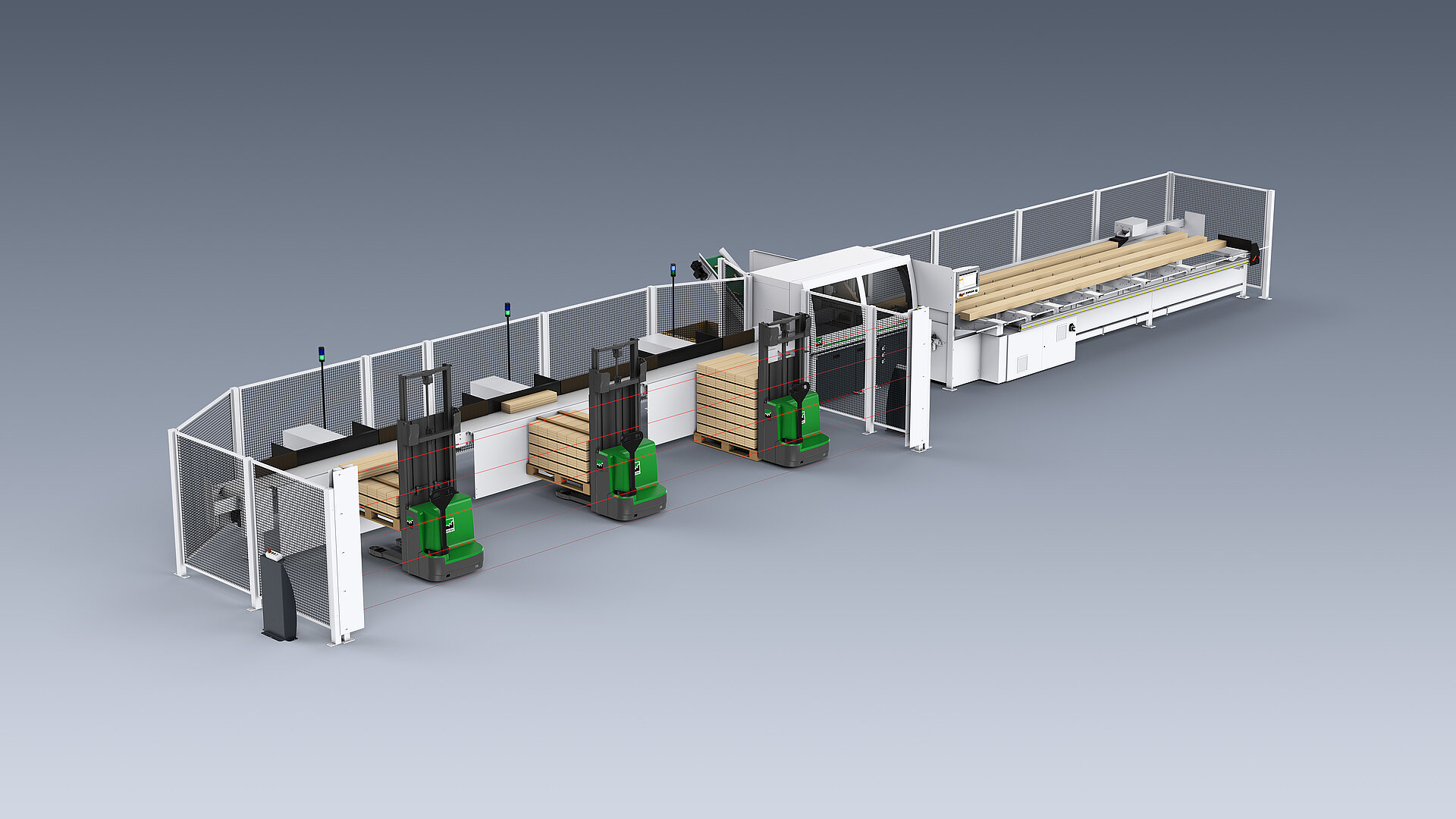

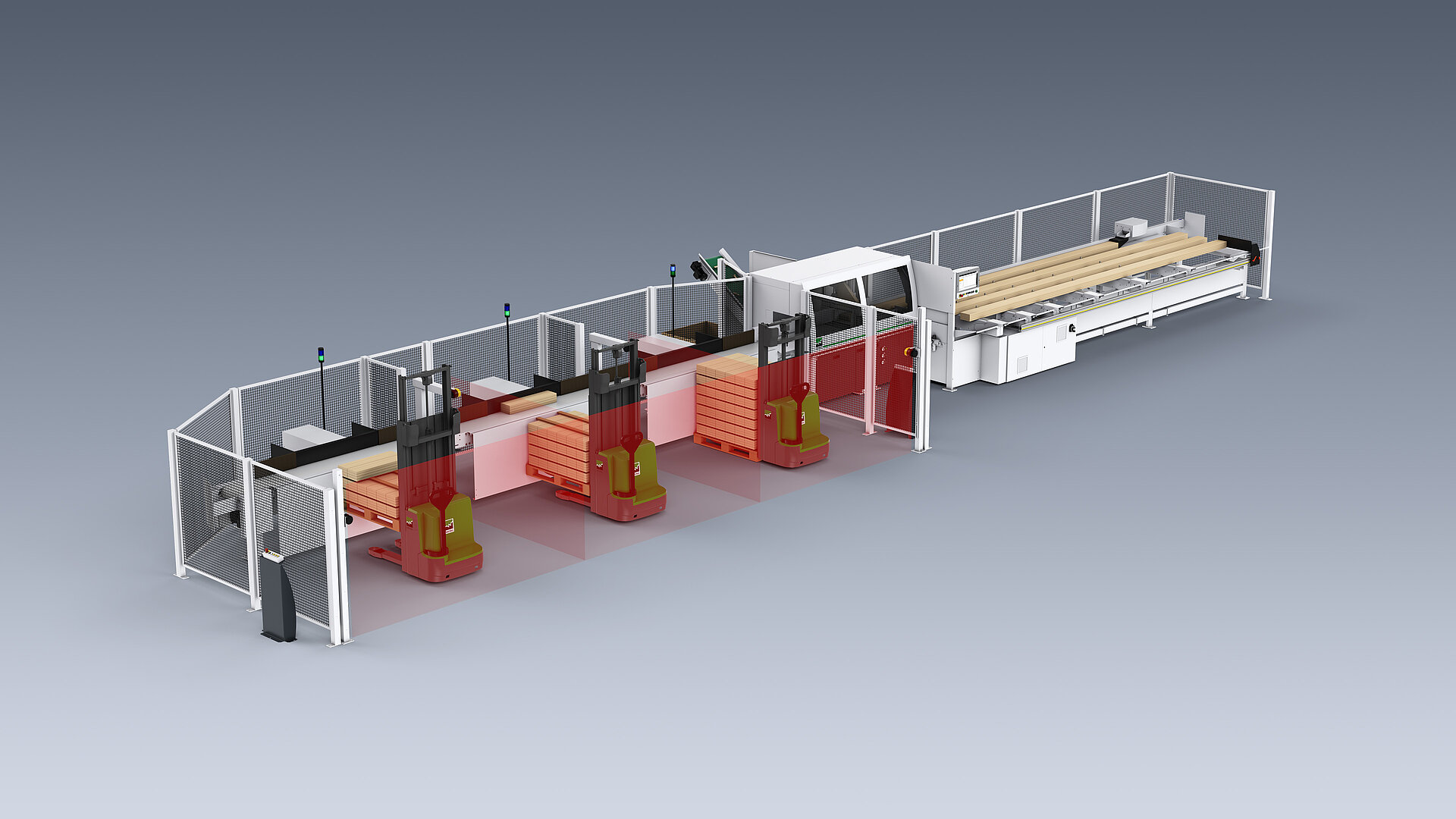

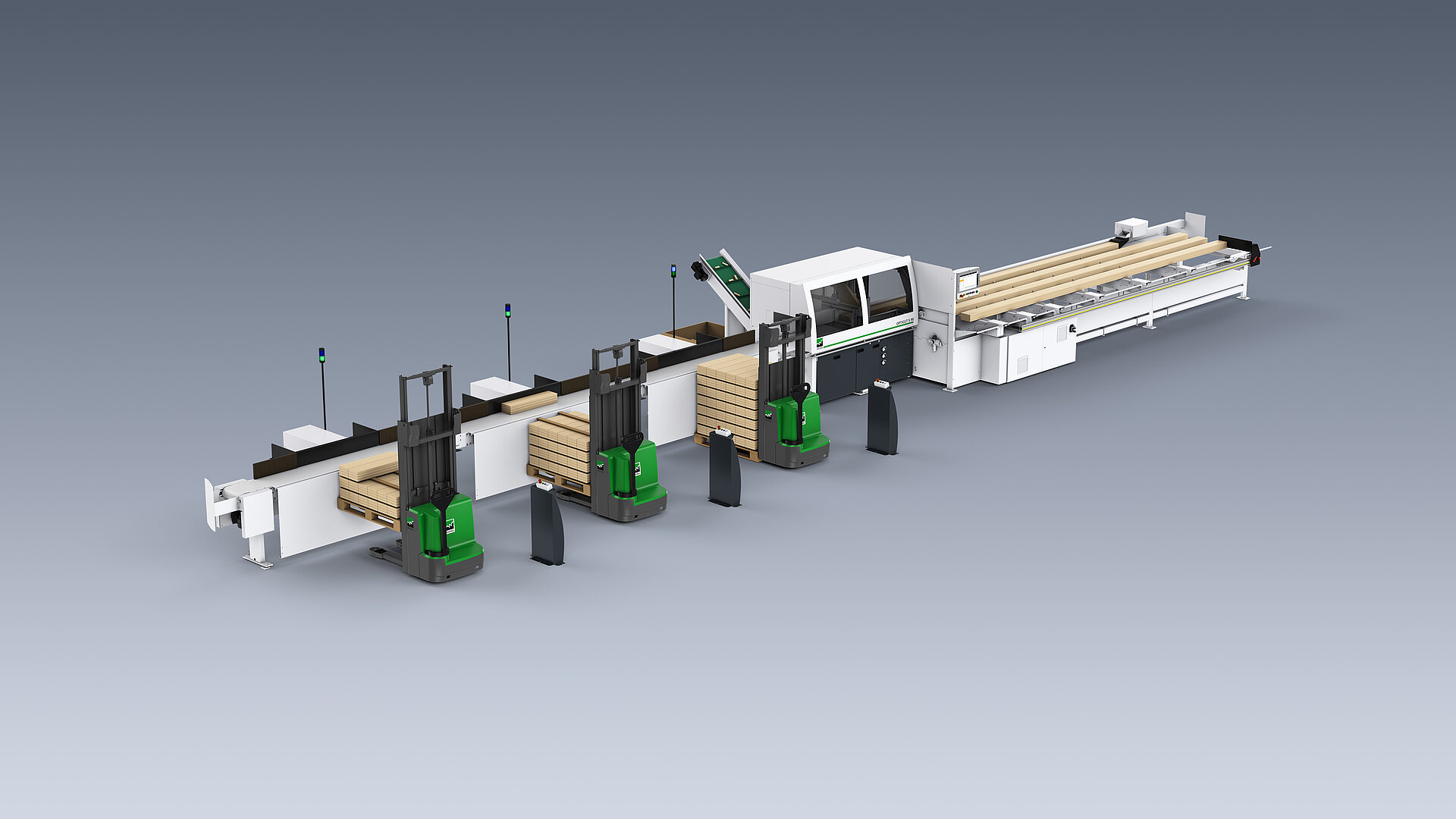

Efficient stacking with the WEINIG EuroStacker Back to previous pagePerformance, flexibility and maximum safety: these characteristics have always been associated to the OptiCut S 50 push-feed saw. The follow up model to this revolutionary machine concept also offers universal possibilities in small and medium-sized operations. The modular design is perfectly matched to your needs to deliver the flexibility you need for future cross-cut saw upgrades. This push-feed saw is the right choice wherever packages or individual boards are cut in large numbers. With optimized cutting, it is possible to cut four times more than with a manual cross-cut saw. This ensures high productivity and maximum yield. There is a lot of potential in lengthwise cutting to increase productivity, profit and added value.

In addition to solid wood, a range of other materials can also be cut, including plastic, aluminum and wooden composites in a great variety of profile shapes. All of this is no problem at all for the OptiCut S 50+. Even large differences in cross section can be processed without having to change the machine parameters significantly.

- Up to four times the performance compared to a manual cross-cut saw

- Reduced unit costs through single-person operation

- Perfectly retrofittable to create a complete cross-cutting center

- Virtually maintenance-free

- Automatic, intelligent waste disposal

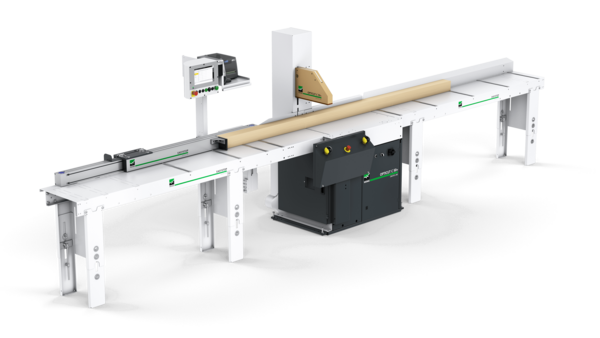

EuroStacker - Stacking made simple

When cutting packages, a single package can easily weigh between 15 and 20 kg – or even more with high wood moisture content. With the WEINIG EuroStacker, the operator only has to position the stacking sticks for each new layer and lower the pallet truck to the next position by pressing a button. All further stacking steps are automatic, leaving you more time for other activities during production. Once the pallet of the electric pallet truck has been filled, the full stack can be transported to the next storage or production location.

The OptiCut S 50+ provides

In order to master new challenges in wood processing, you need an advanced, efficient and economical production organization. Automated, networked processes are the most important prerequisite for this. A central component is digitization, which ensures extensive exchange of information between man and machine. With the OptiCut S 50+, numerous software solutions such as OptiPal, OptiResult and OptiStore can be used for process optimization.

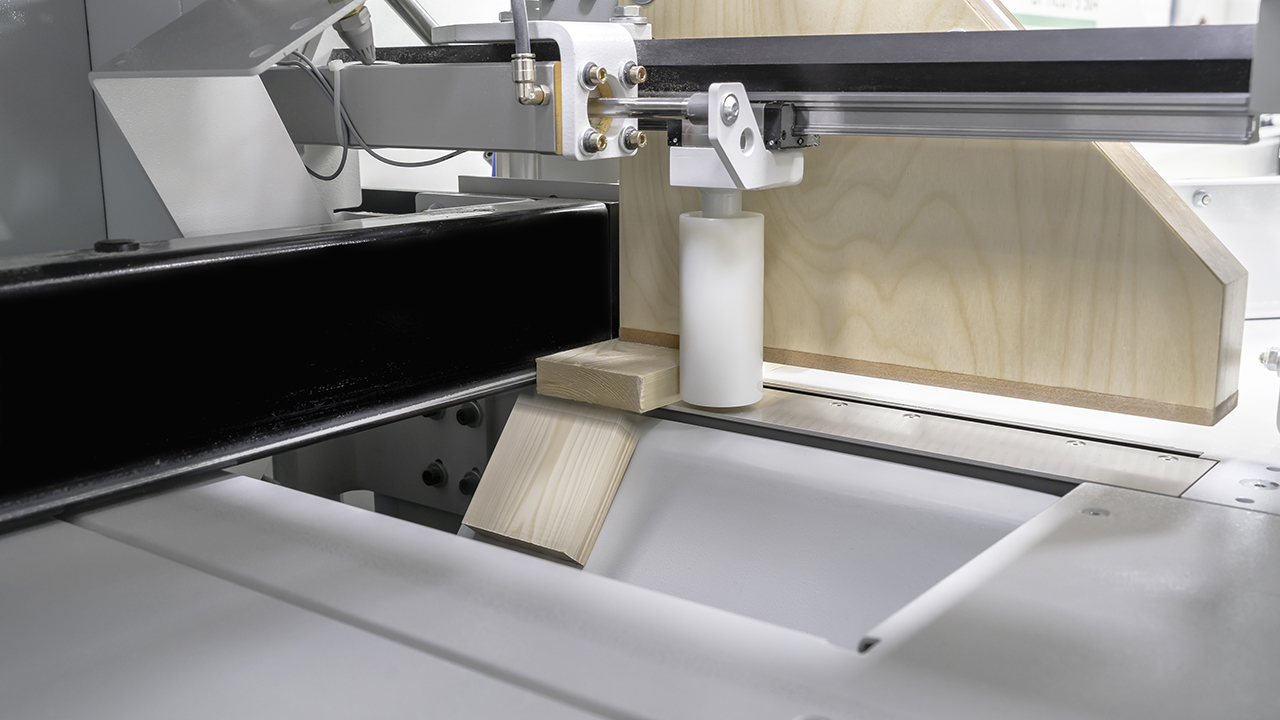

The workpiece clamping system optionally consists of a side guide and pressure roller. The side guide ensures the alignment and pre-clamping of the workpieces, so that a perfect cut can always be made. The swiveling lateral pressure roller in the outfeed presses the workpiece against the fence after the saw blade, ensuring precise right angles even for the last cuts.

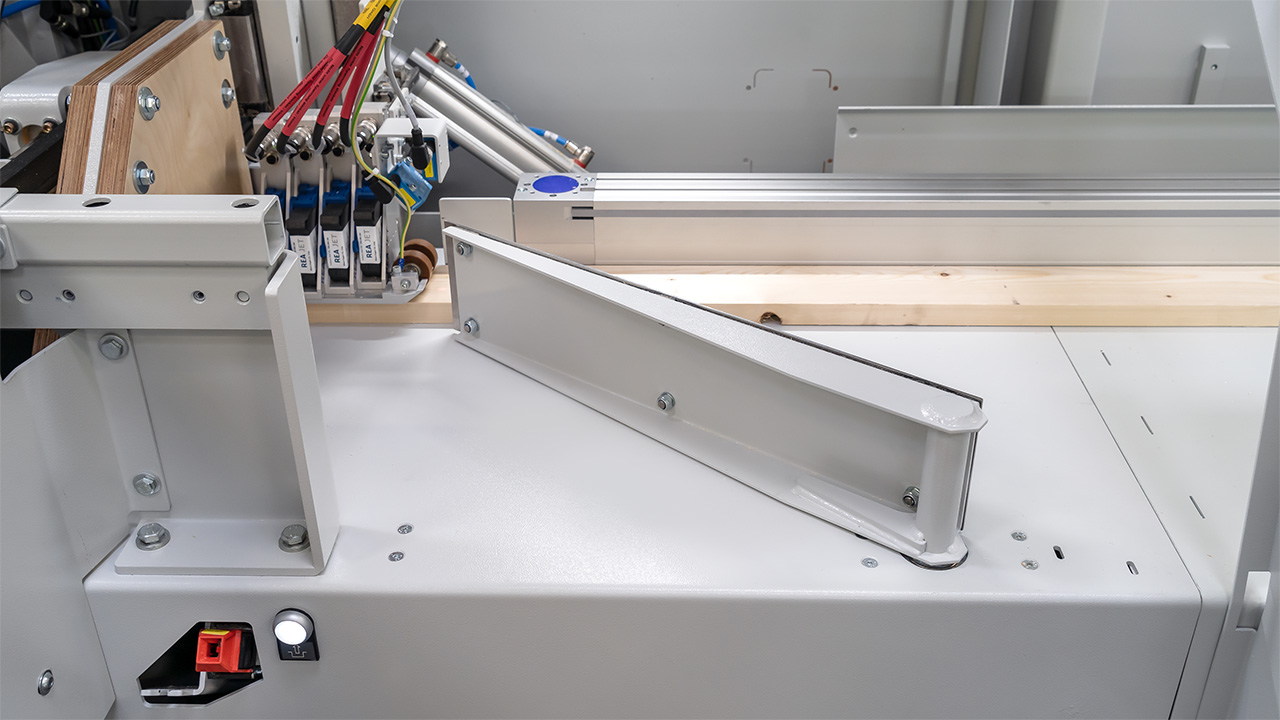

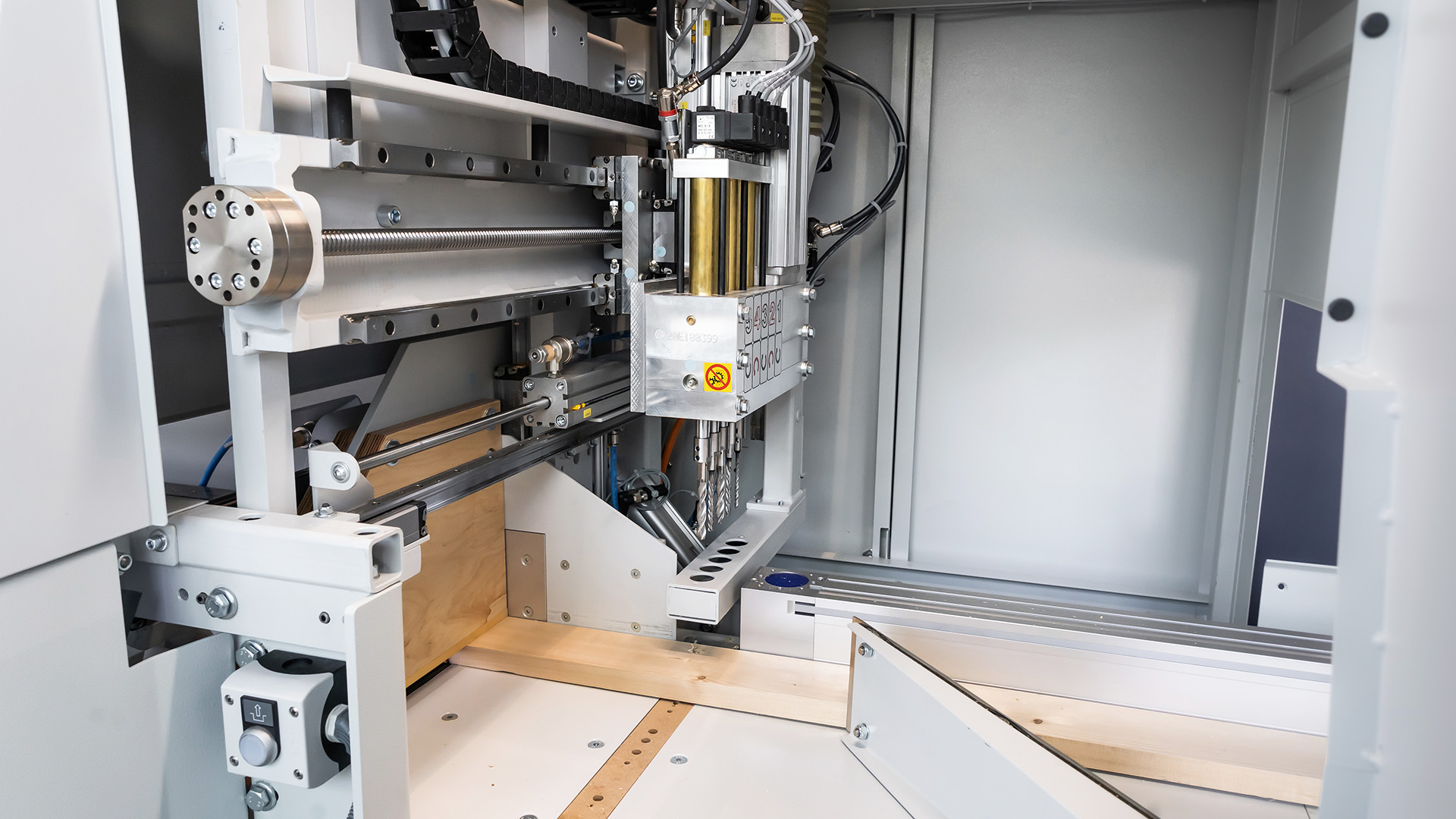

Powerdrill drilling unit

The Powerdrill unit has been specially developed for use with the OptiCut S 50+ optimizing cross-cut saw. Equipped with five drilling spindles, the drilling head allows the use of different drilling tools. The unit can be combined as required with existing options and configurations, such as automatic cross-feeding or sorting. In the machine body, the drilling unit is located upstream of the sawing unit. The unit is designed with high-quality components for precise positioning along the workpiece width (y-axis) and along the workpiece height (z-axis). In the longitudinal direction of the workpiece (x-axis), conveying is carried out with the positioning pusher. A wide variety of pressure options can be used for clamping the workpiece upstream and downstream of the sawing unit.

The OptiCut S 50+ with Powerdrill in use

WEINIG visited our customer "herbholz" from Engstingen-Kohlstetten in Germany. The Swabian company has owned the OptiCut S 50 + with the Powerdrill drilling unit since the beginning of 2022. The combination of cross-cut saw and drilling unit has convinced them.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/d/csm_Header_Holz-Handwerk_2023_a6ad700671.jpg)