EasyScan Smart C

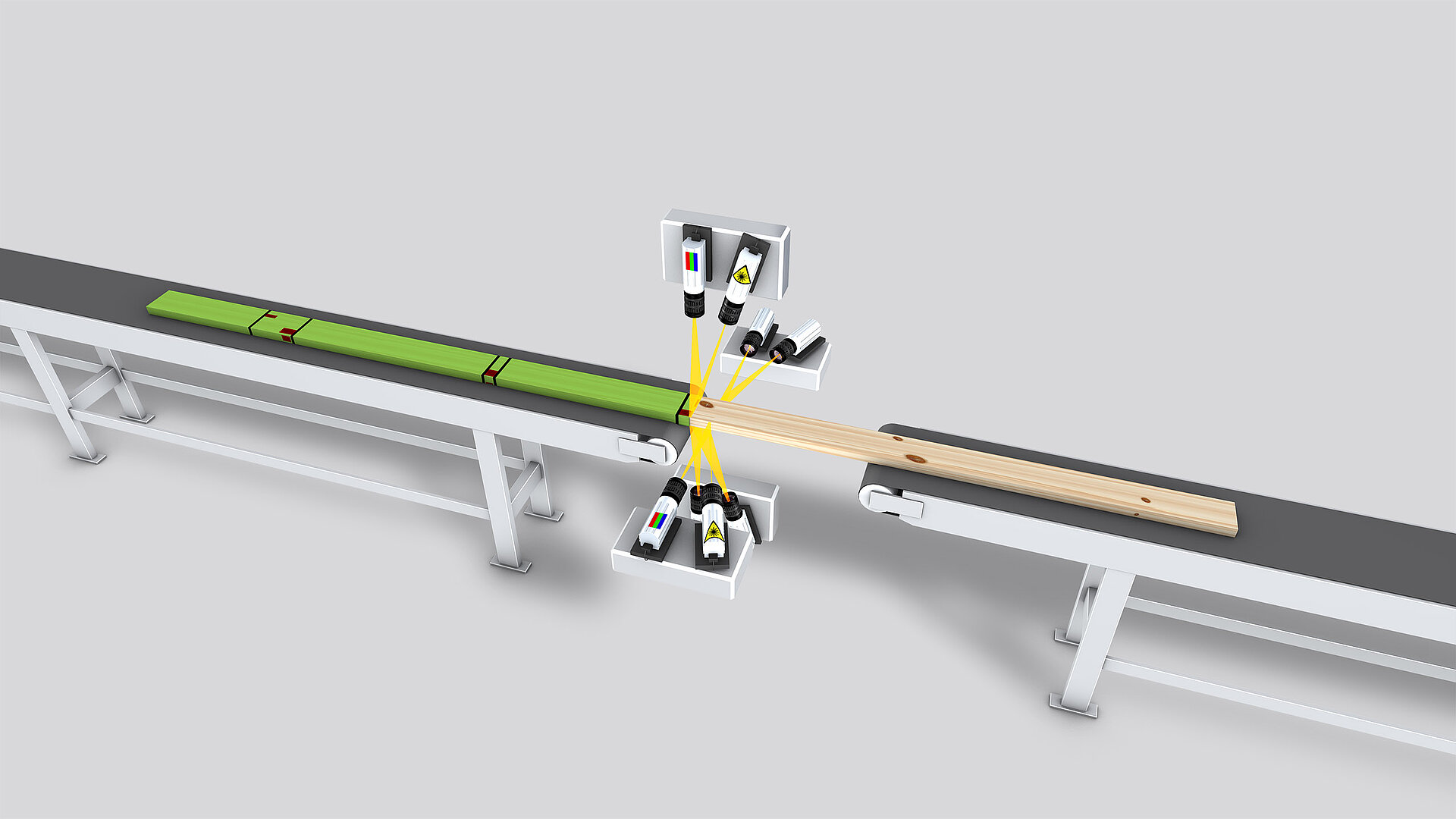

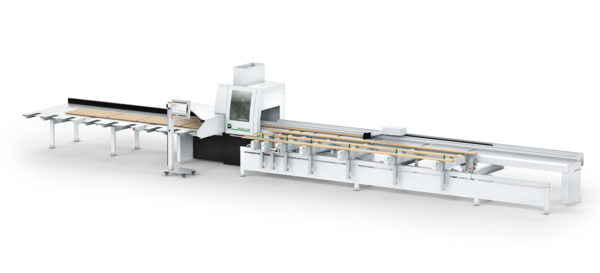

The intelligent scanner for profitable cross-cutting and sorting Back to previous pageIn advanced woodworking, the automation of defect detection is the key to efficient, high-performance production. An upstream scanner is a key component of the entire system. The EasyScan Smart C detects wood defects (such as knots, wane, holes, etc.) on softwood and hardwood at lightning speed and feeds one or two optimizing cross-cut saws at full production speed. Together with OptiCore software, the EasyScan Smart C not only brings completely new optimization opportunities to your production, but also offers maximum production control and transparency in your manufacturing process at a low price level. Its compact design allows it to be used as an upgrade for existing and new lines. From small entry-level systems to large production facilities - the EasyScan Smart C is a reliable partner.

- Relevant wood data on all sides with laser and color cameras

- 3D lasers capture and visualize workpieces

- OptiCore AI supports defect detection on the most common types of wood and optimizes the yield

- Angle Crack Module (ACM)improves detection of oblique cracks

- Dual scatter enables fiber analysis and ensures superior cutting accuracy

- Automatic camera adjustment

Cross-cutting

The EasyScan Smart C was specially developed for cross-cutting applications. The scanner can be upgraded with multiple options for different requirements, offering optimal flexibility. Choose the type of optimization, define complex products and link the scanner directly to your networked production: This way you are clearly ahead of your competitors!

The EasyScan Smart C provides

The EasyScan Smart C was specially developed for cross-cutting applications. The scanner can be upgraded with multiple options for different requirements, offering optimal flexibility. Choose the type of optimization, define complex products and link the scanner directly to your networked production: This way you are clearly ahead of your competitors!

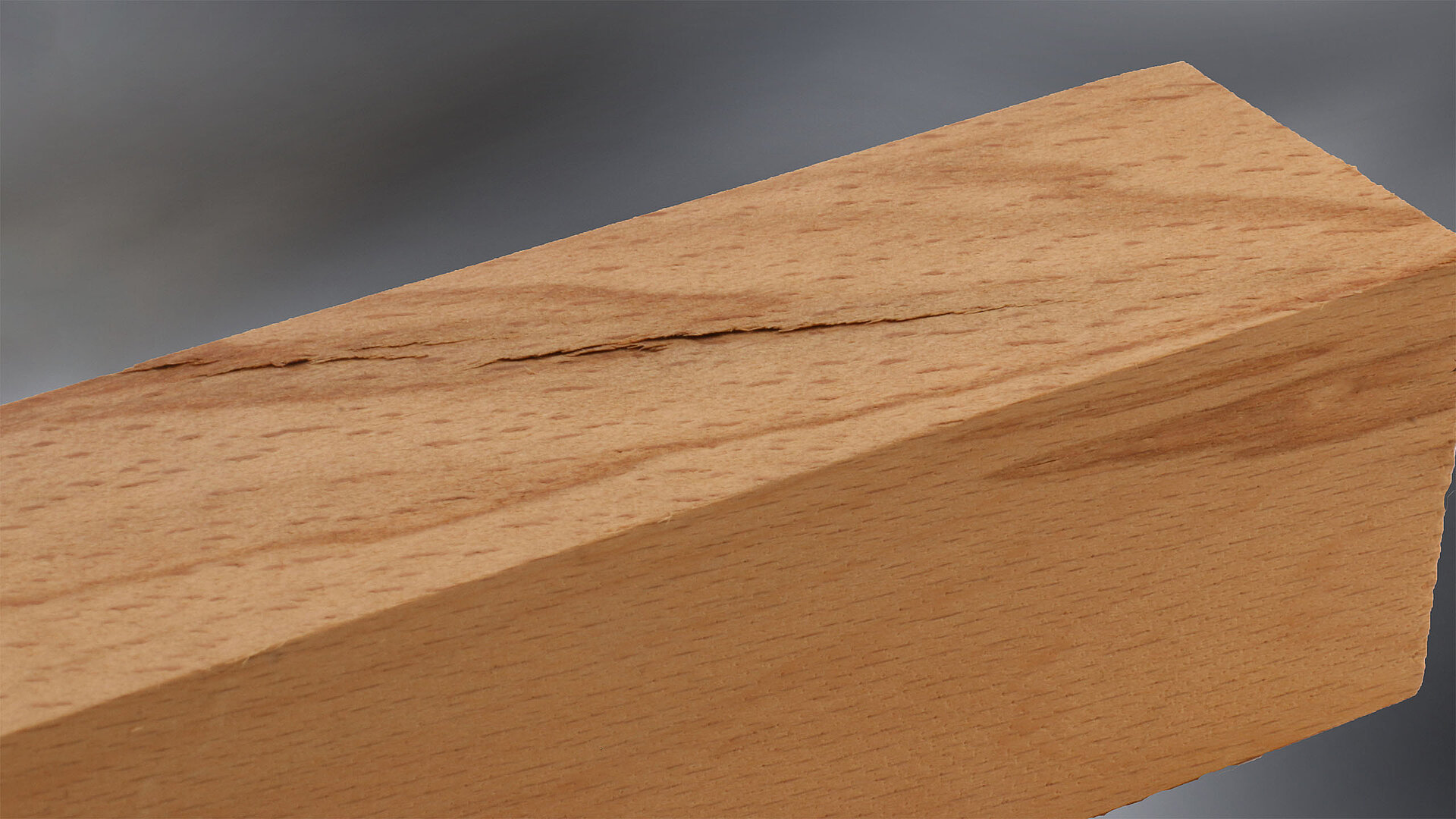

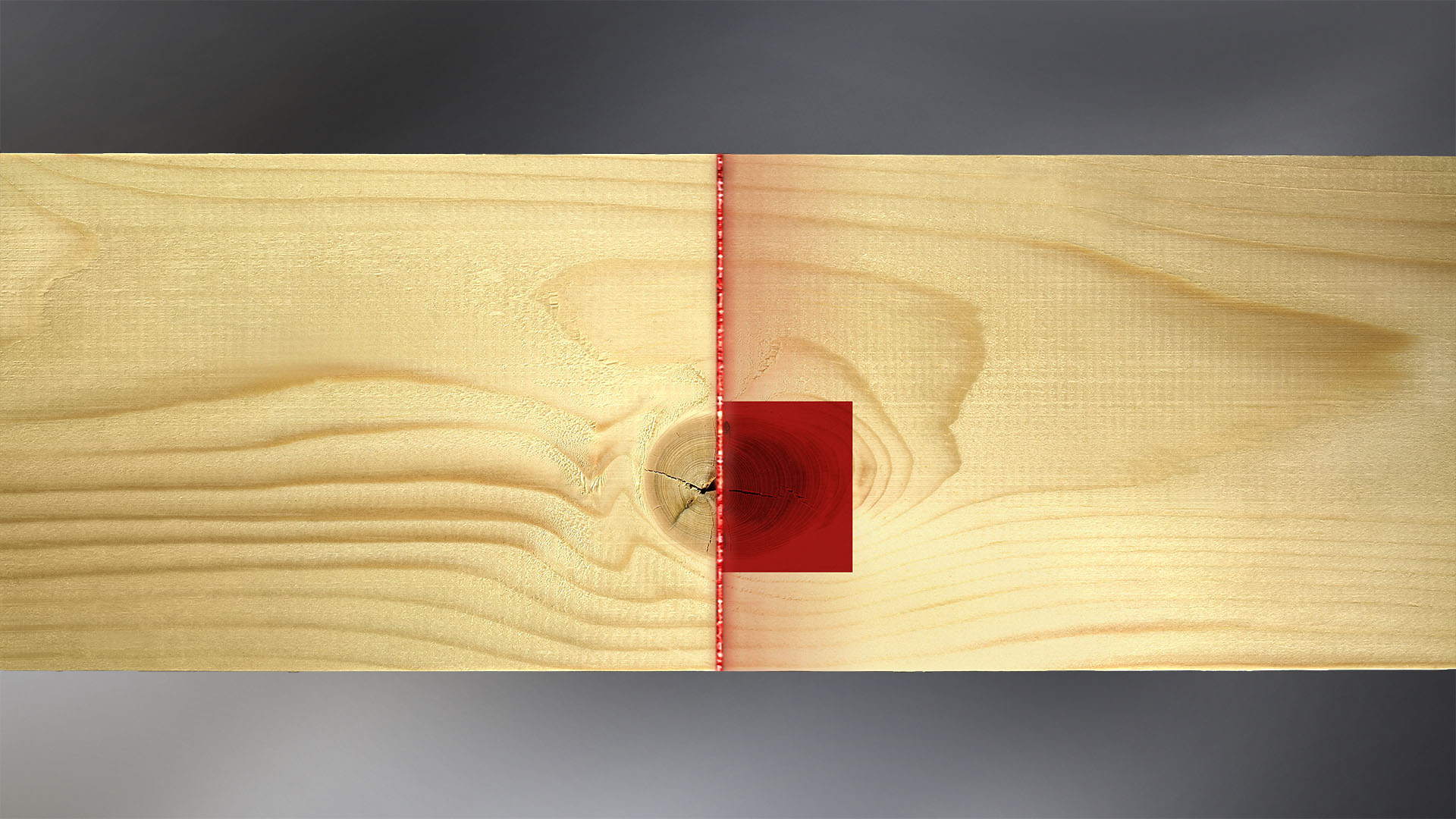

The detection of oblique, non-vertical cracks has been difficult. Thanks to the use of four additional, specially positioned lasers, the Angle Crack Module is able to provide further information. In the event of non-vertical cracks on the top and bottom sides, an additional contrast is created, which allows the detection of cracks that are normally difficult to identify. This also improves overall crack detection and minimizes the risk of over-detection.

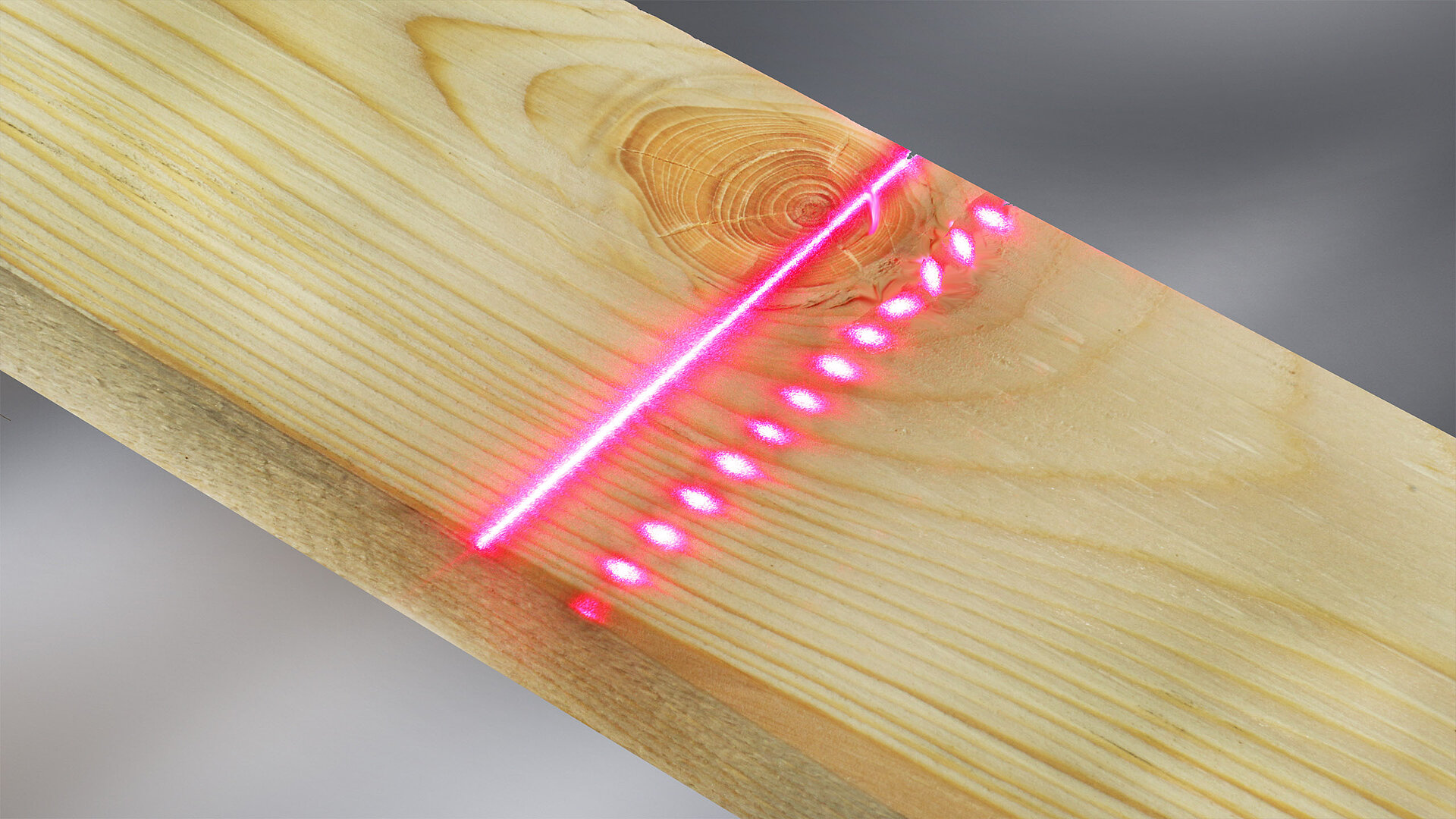

An essential component of maximizing recovery and increasing value is a precise cutting position, particularly with finger jointed products. The “dual scatter” system comprising a line- and a dot laser enables this precision. While the line laser is primarily used to detect knots, cracks and resin pockets, the dot laser provides improved detection, especially on rough surfaces. The cutting position is more accurately defined using the angle and size of the dots. This guarantees stable finger jointing. This option is available for hardwood and softwood.

The straightforward design of the EasyScan Smart C goes hand in hand with user-friendly software. A reduction in adjustment and maintenance time means an increase in production time and throughput. Therefore, the scanner features automatic camera adjustment which positions all cameras ideally to enable excellent image quality and resolution. It also reduces operator error, thus keeping production losses to a minimum.

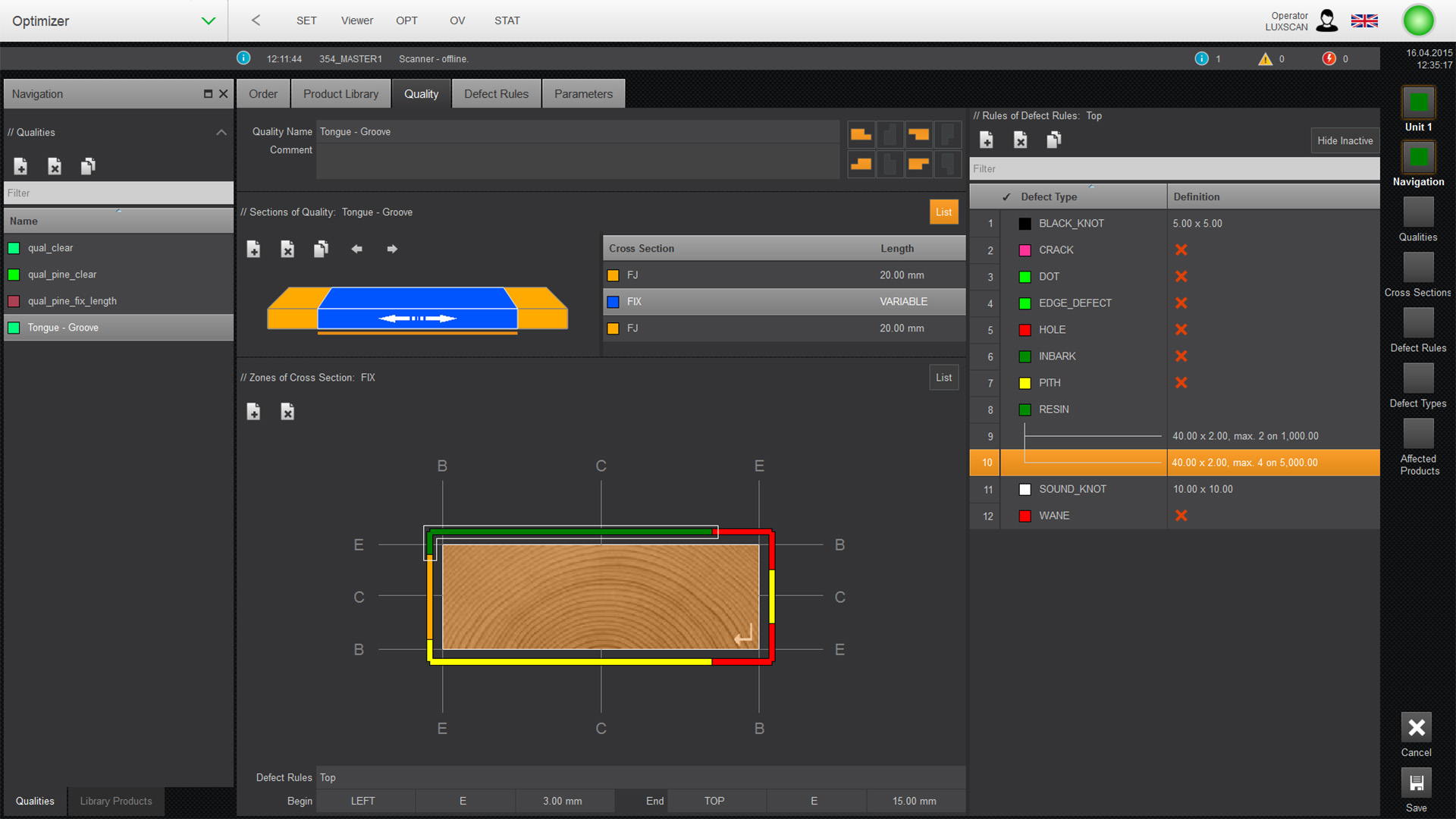

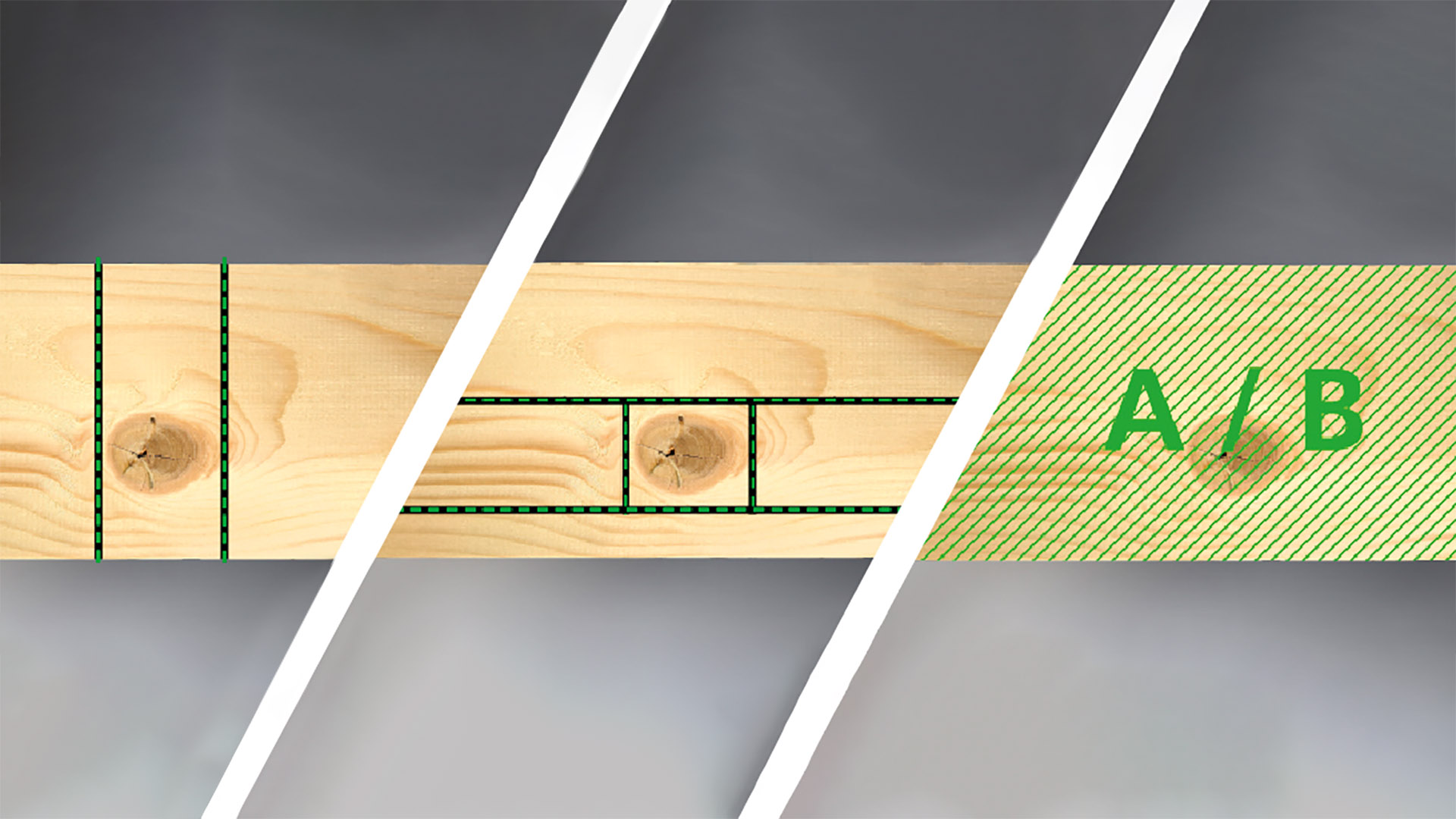

Manage your production optimally with OptiCore. The software allows you to define your products and their required qualities very precisely. The sensors detect each individual piece of wood and the optimization software calculates the highest possible yield, taking into account your quality requirements. Your product details and qualities are stored in the database and can be quickly selected again via drag-and-drop if required. Thanks to simple and logical user guidance, OptiCore can be operated quickly by any employee.

OptiCore AI software with artificial intelligence

OptiCore AI is an intelligent image processing software that uses deep learning, a class of neural networks from the field of artificial intelligence, to recognize the wood features. This method can significantly improve recognition accuracy as the software learns to process images like a human brain. With OptiCore AI, the scanner can be trained to automatically analyze and detect wood defects according to predefined parameters. The results and their repeatability are thus significantly improved and the setup time is reduced.

Step 1:

The scanners are based upon various sensors, such as laser and color cameras. Your WEINIG expert defines the right sensors and the best combination of these, matched to the wood species, surface quality and customer requirements. Our objective is to achieve the best possible quality of information for any required application.

Step 3:

Optimization via the high-performance OptiCore software calculates the best solution during cross-cutting, ripping (not available in all scanner models) and sorting. In doing so, it takes into account the various customer requests and requirements. Based upon the precise board data calculated during image processing, the board is optimized in accordance with the defined requirements. This allows a virtually unlimited number of qualities and products to be defined. This means that even a complex product mix can be ideally optimized to produce almost any type of end product.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/d/csm_Header_Holz-Handwerk_2023_a6ad700671.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/e/csm_SOLID_CNC_CR_400_V_911f3ce129.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/a/csm_SOLID_PROFILE_P_500_a859b40322.png)