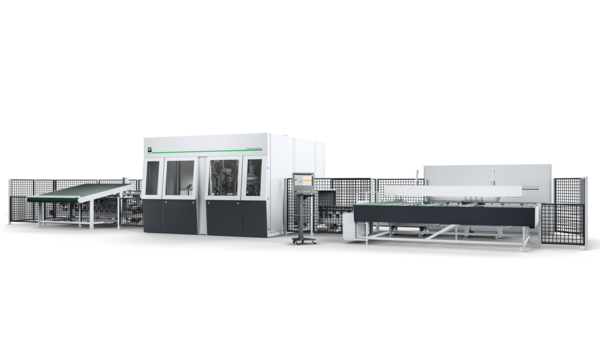

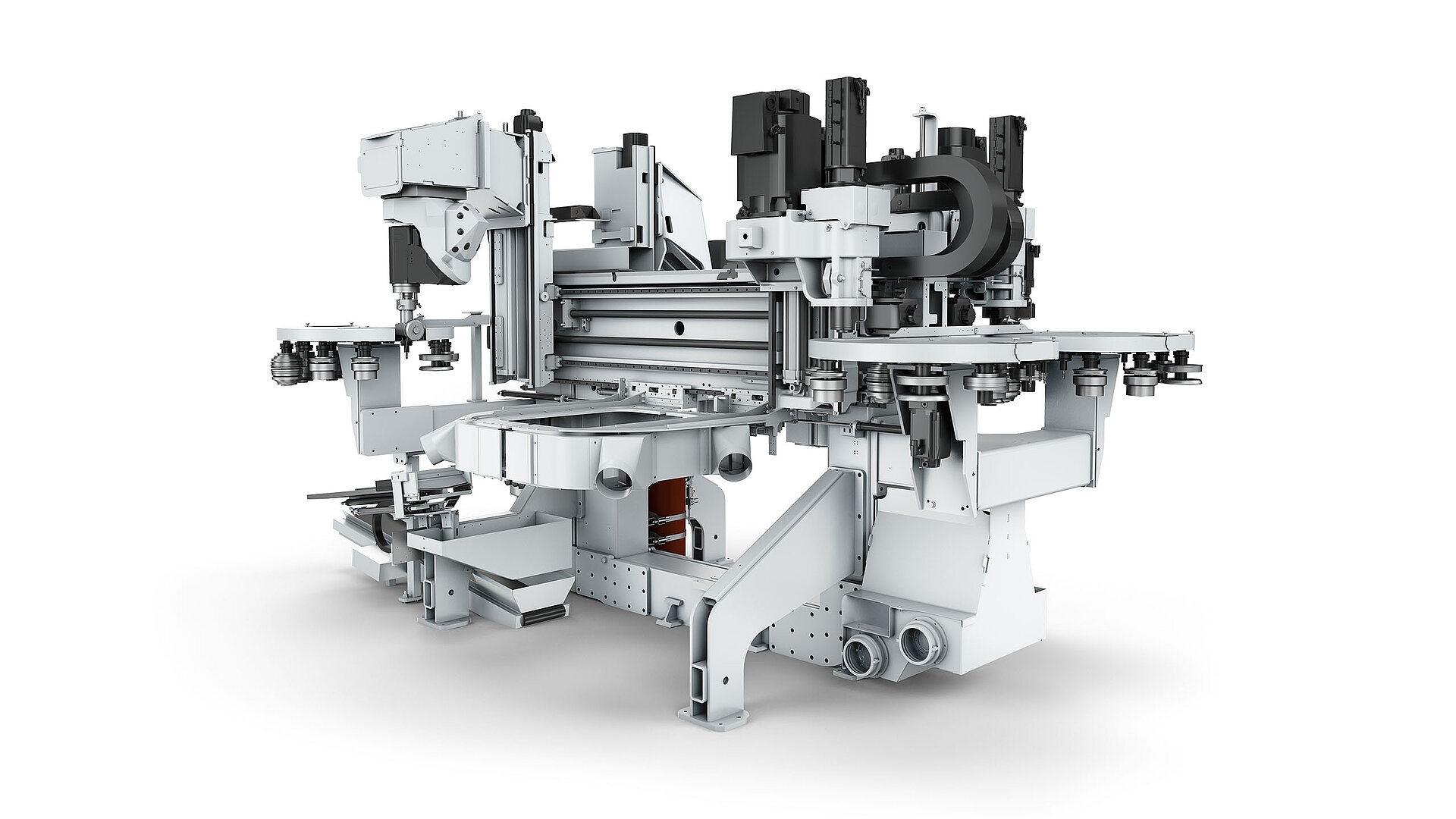

Conturex Vario XS

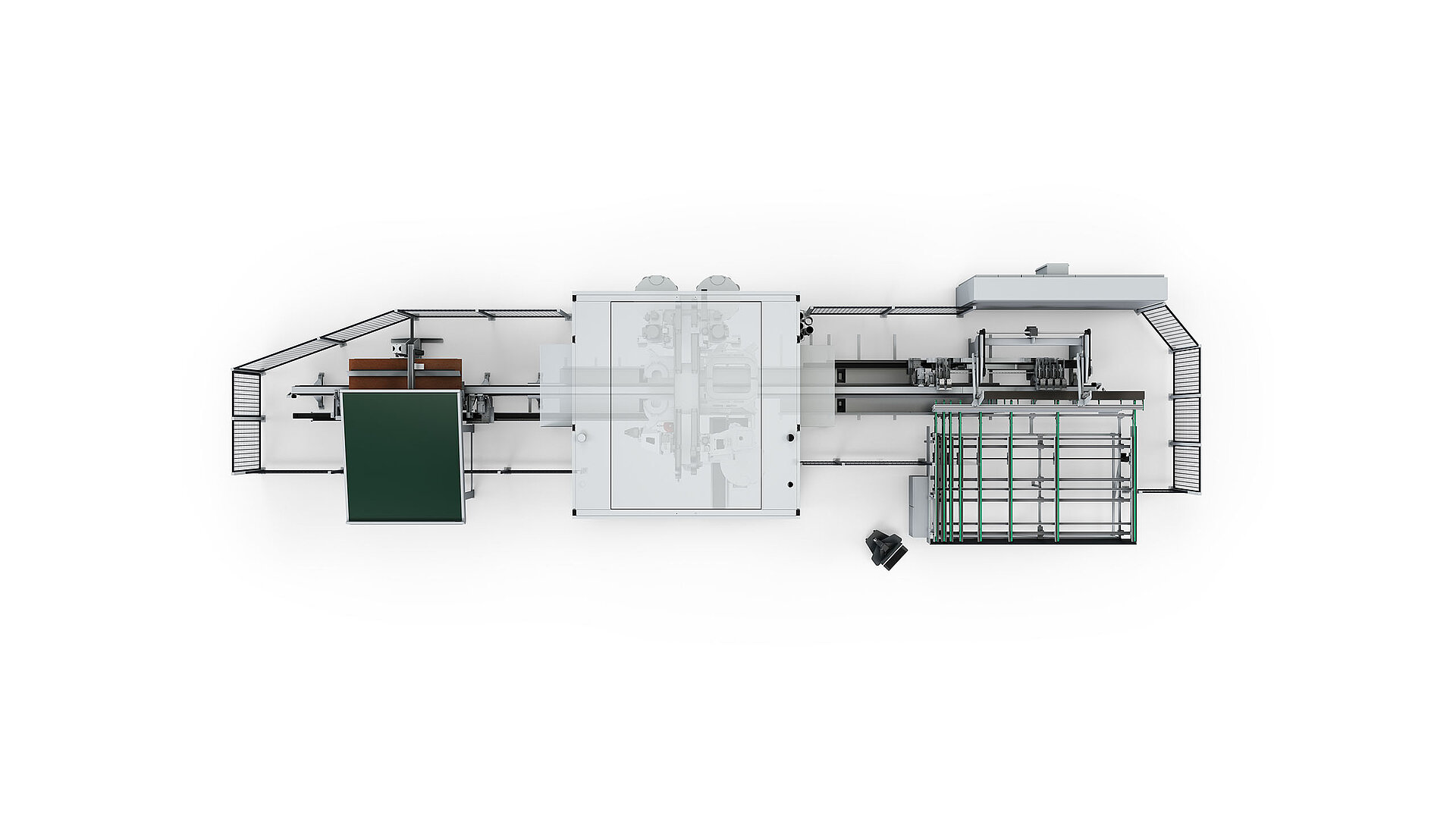

XS machine, XXL possibilities Back to previous pageThe Conturex XS offers unlimited processing options in the smallest space, adapts perfectly to today's market requirements and sets standards for the future. Thanks to the integration of PowerGrip Motion 2D/3D, the smallest of all Conturex Varios is in no way inferior to its big brothers S & L. It enables setup-free complete processing in a single clamping process and full freedom of movement in X, Y and Z directions. The Vario XS enables not only industrial companies, also smaller craft businesses, to think in completely new dimensions - both in batch size 1 and in series production.

- Robust machine body

- WEINIG Machine Control (WMC)

- WEINIG WOP

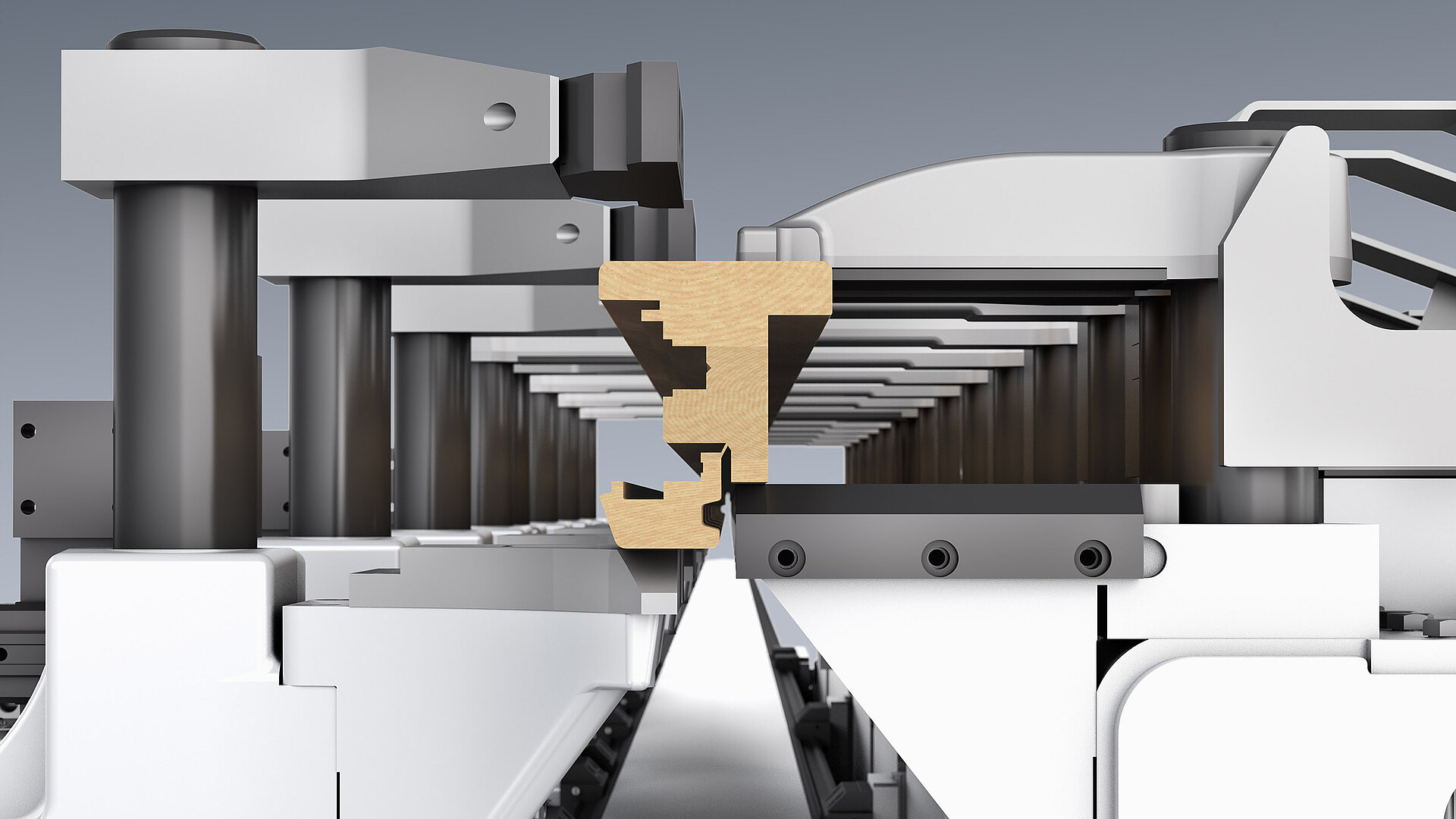

- Maximum undercut height

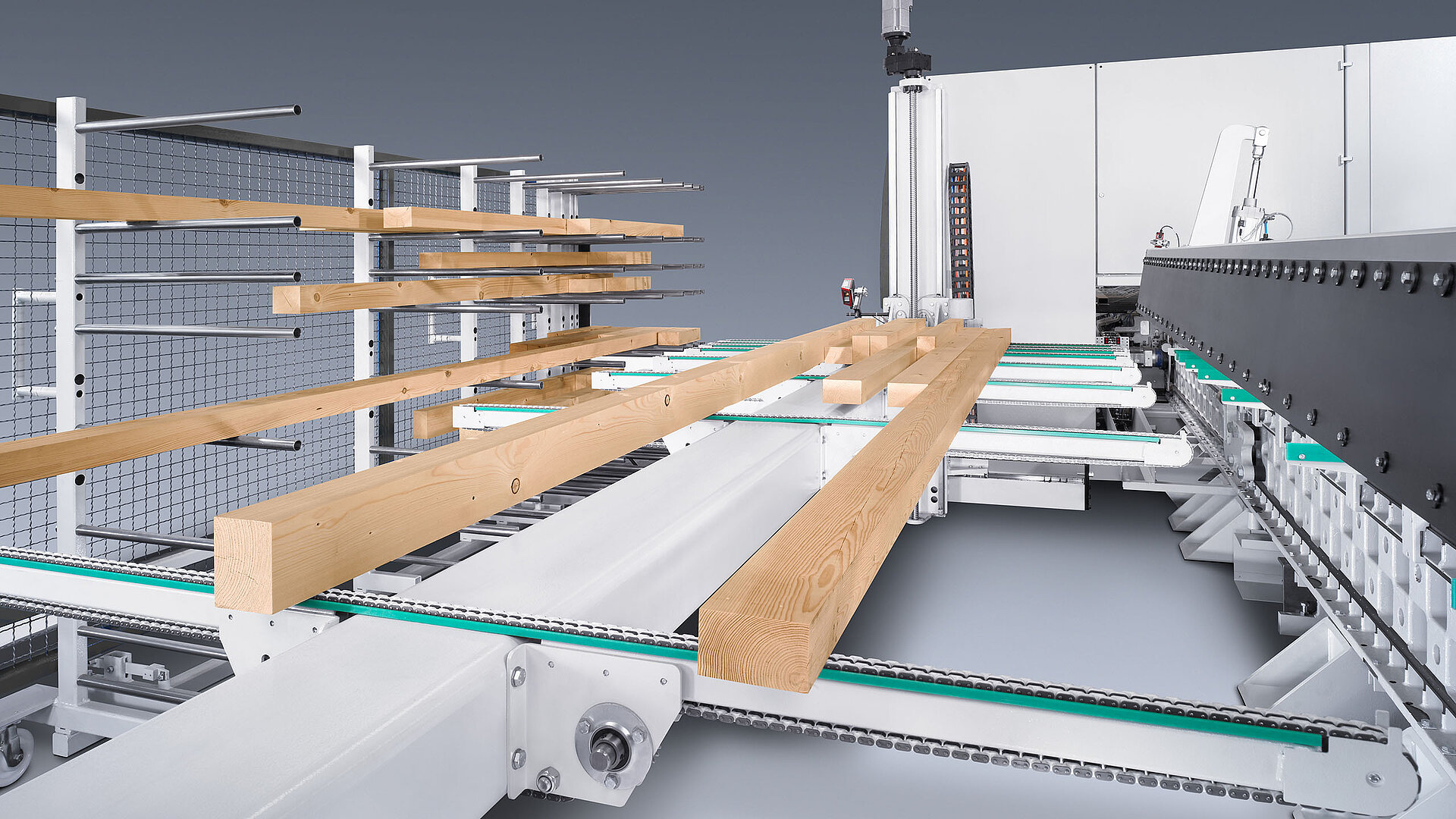

- High degree of automation

- Wide range of equipment variations

The Conturex Vario XS provides

Due to the high level of automation, this XS machining center allows you to operate efficiently with minimal manpower. Short setup times and fast throughput help you achieve a high degree of machine utilization. Thanks to perfectly matched units, the Conturex Vario XS enables you to react quickly and flexibly to changes or new requirements. “Just-in-time” production on a commission basis can be easily implemented thanks to optimized tool systems. All in all, the Conturex Vario XS gives you the benefit of increased performance that enables you to tap into new market segments with ease.

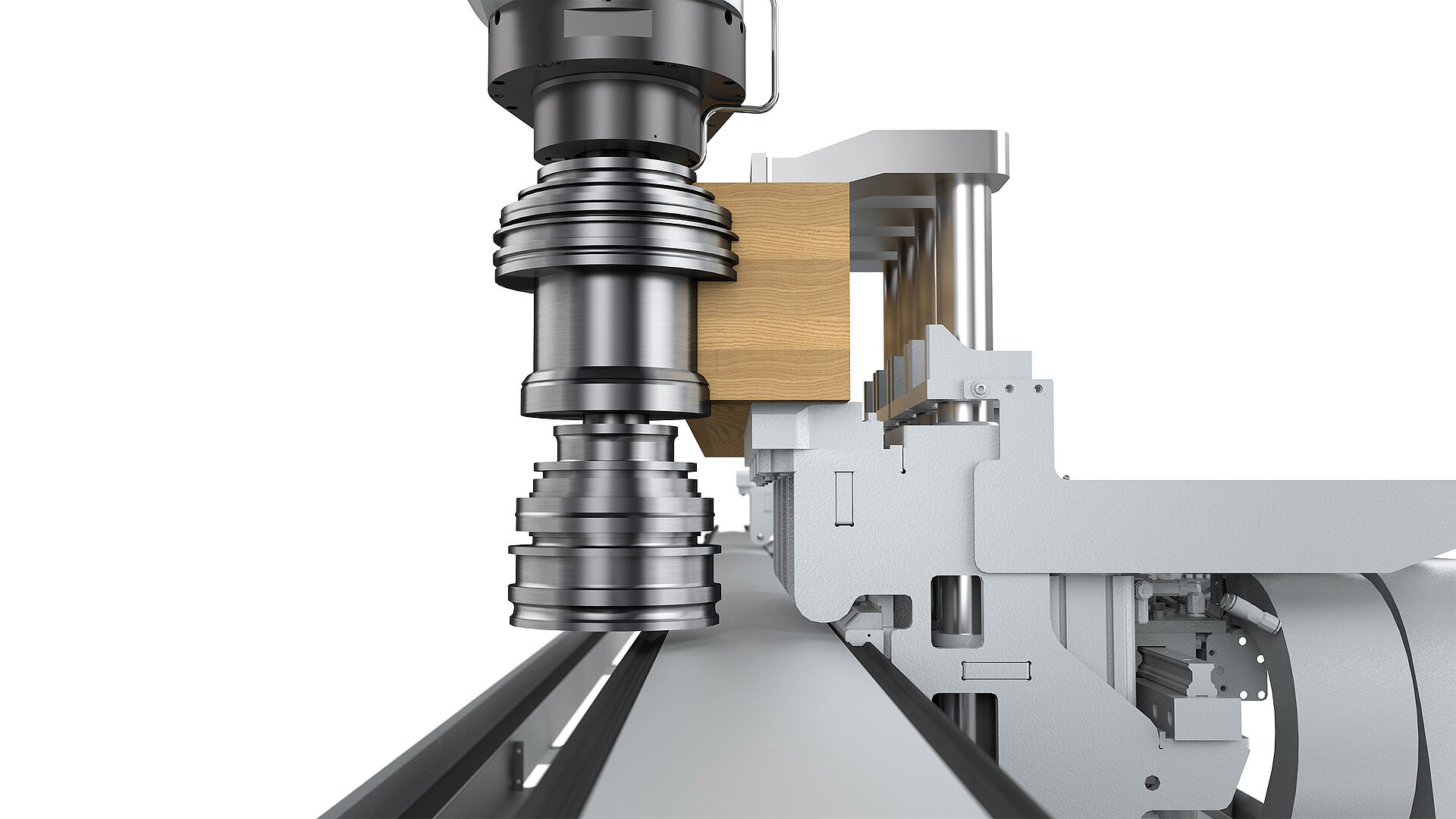

With PowerGrip Motion 3D, widths of up to 330 mm, but also the smallest dimensions, can be clamped safely and processed flexibly. The high degree of dimensional precision, profile accuracy and excellent surface quality of all workpieces speaks for itself. The patented clamping elements are programmed with the help of smart software solutions and individually controlled with the WMC control system. The clearly arranged PC interface makes work much easier for the machine operator.

Thanks to its innovative machine cabin, the Conturex Vario XS is easily accessible for maintenance work. Clear glass panes guarantee optimum visibility into the machine so that you can easily monitor the production process. The CE-compliant fully enclosed machining area ensures the safety of everyone near the machine. Additional protection is provided by the separation of the HSK spindle and motor, the integration of standard air-cooled motors, and separate password-protected release for production.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/d/csm_Header_Holz-Handwerk_2023_a6ad700671.jpg)