![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/5/csm_Header_P700_74bb5f2883.png)

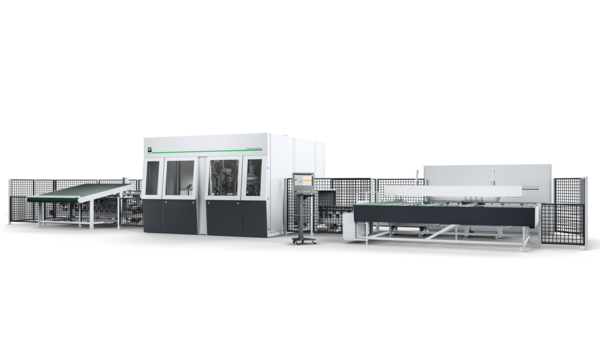

Powermat 700

The power house for window manufacturers for planing scantlings and profiling moldings Back to previous pageThe Powermat 700 has a sophisticated operating concept that is different from any other moulder in this performance class. The result: improved operator comfort and the shortest setup times ensure maximum flexibility. That’s why the Powermat adapts perfectly to today’s market requirements and sets new standards in four-sided machining.

- High production accuracy

- High work safety

- Modular design

- Innovative machine engineering

WMC - WEINIG Machine Control

The core function of WMC is the dashboard, which provides the operator with a comprehensive overview of all relevant performance data. The operator can customize the dashboard to the requirements of his product to have all important information at a glance. The simple user interface enables short training times for new operators. WMC's range of functions oriented towards the needs of its customers, and the control system can be expanded with optional modules, such as a digital maintenance plan, depending on requirements. Since the beginning of the year, WMC has also been available on the Powermat 700, which means that craft businesses can now also enjoy the benefits of the most convenient control system for moulders on the market.

The Powermat 700 provides

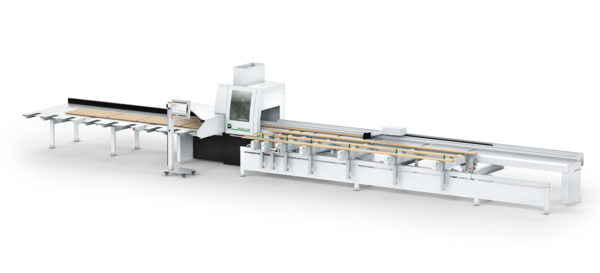

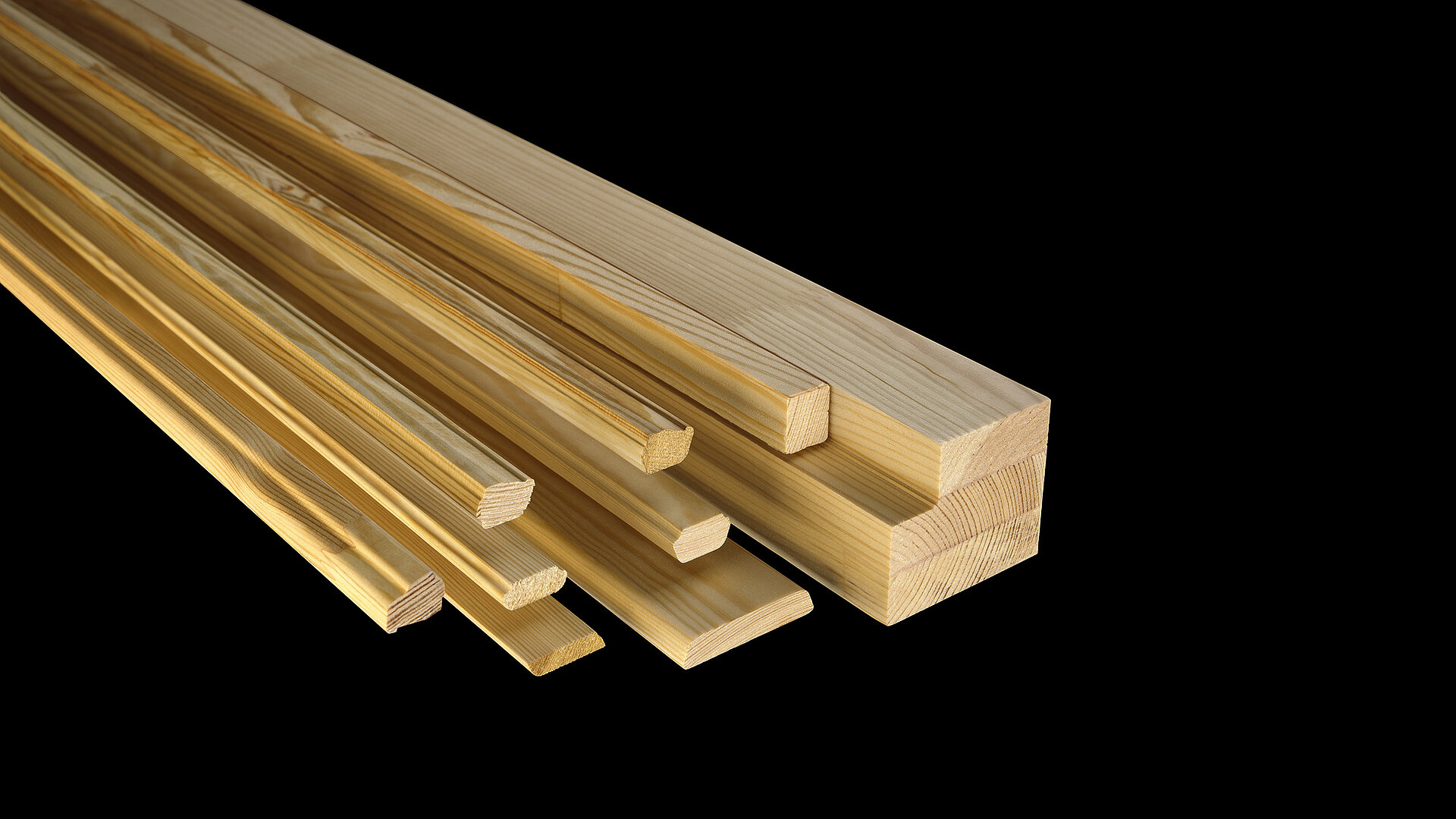

With the window package, you can plane out scantlings as well as profile moldings.

The package includes:

Glazing bead removal after 2nd HO pneumatically clocked

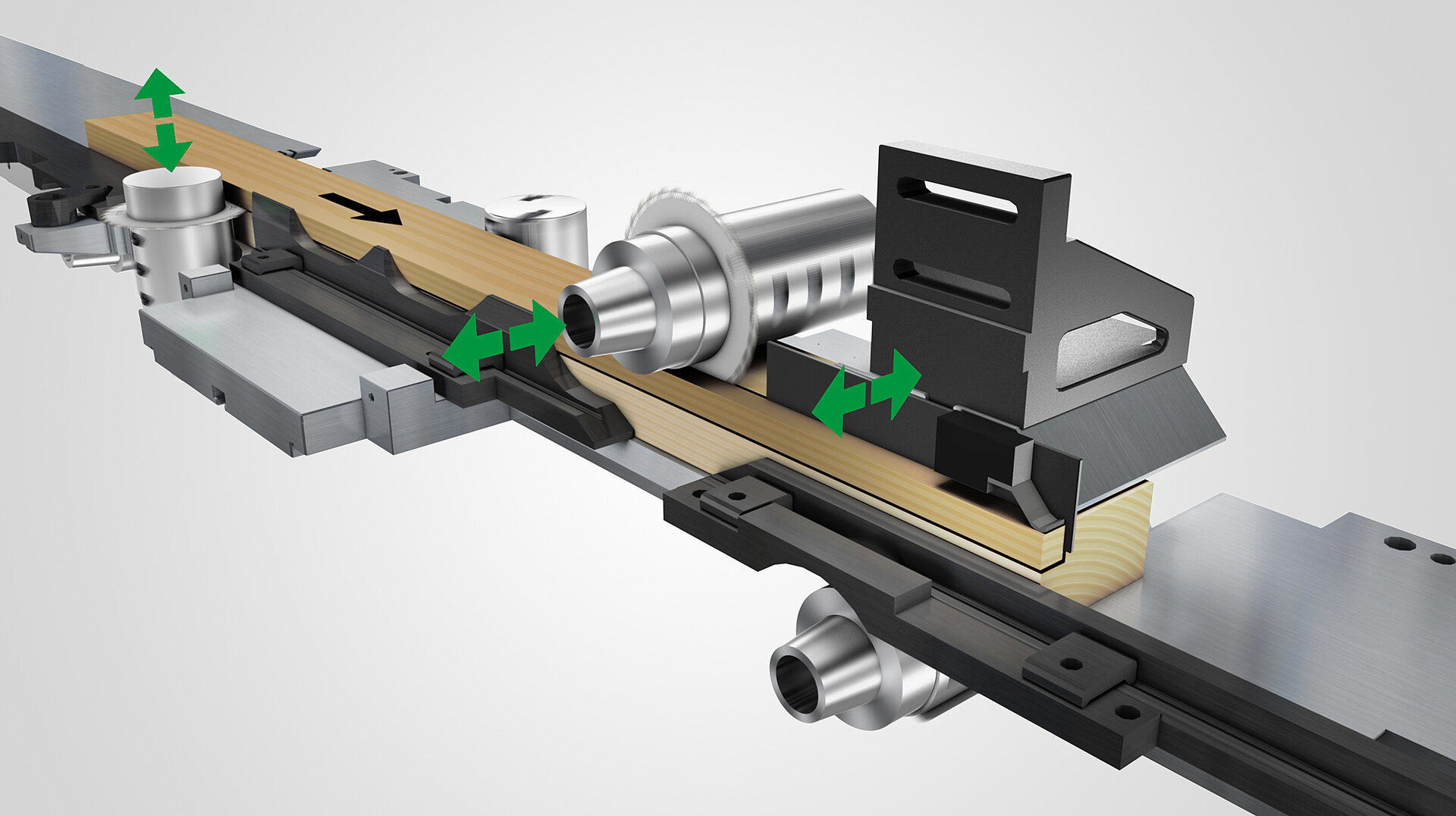

Guide ruler running along after left tool holder

Air cushion system in the machine table

Lateral feed for single part production from 350 mm length

A major benefit of the new operating concept is the reduction of setup time and downtime to a minimum. Proven options such as the Power Lock tool system offer additional potential in this area. This allows operators to make full use of the Powermat’s flexibility, and even frequent profile changes or small batch sizes do not represent a disadvantage for the economic efficiency of your production.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/d/csm_Header_Holz-Handwerk_2023_a6ad700671.jpg)