![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/e/csm_SOLID_PLANE_CUBE_ea65426392.png)

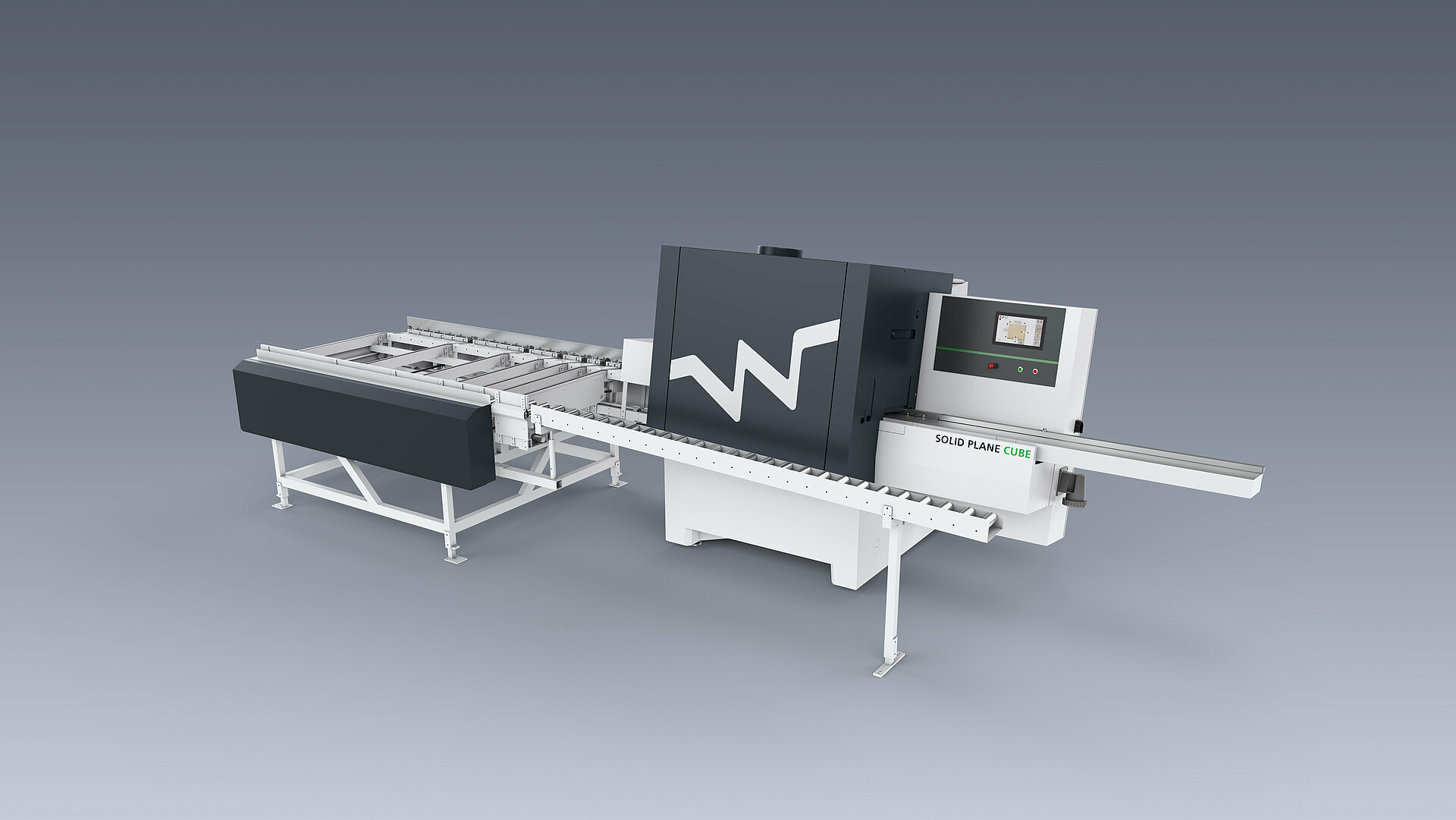

SOLID PLANE CUBE

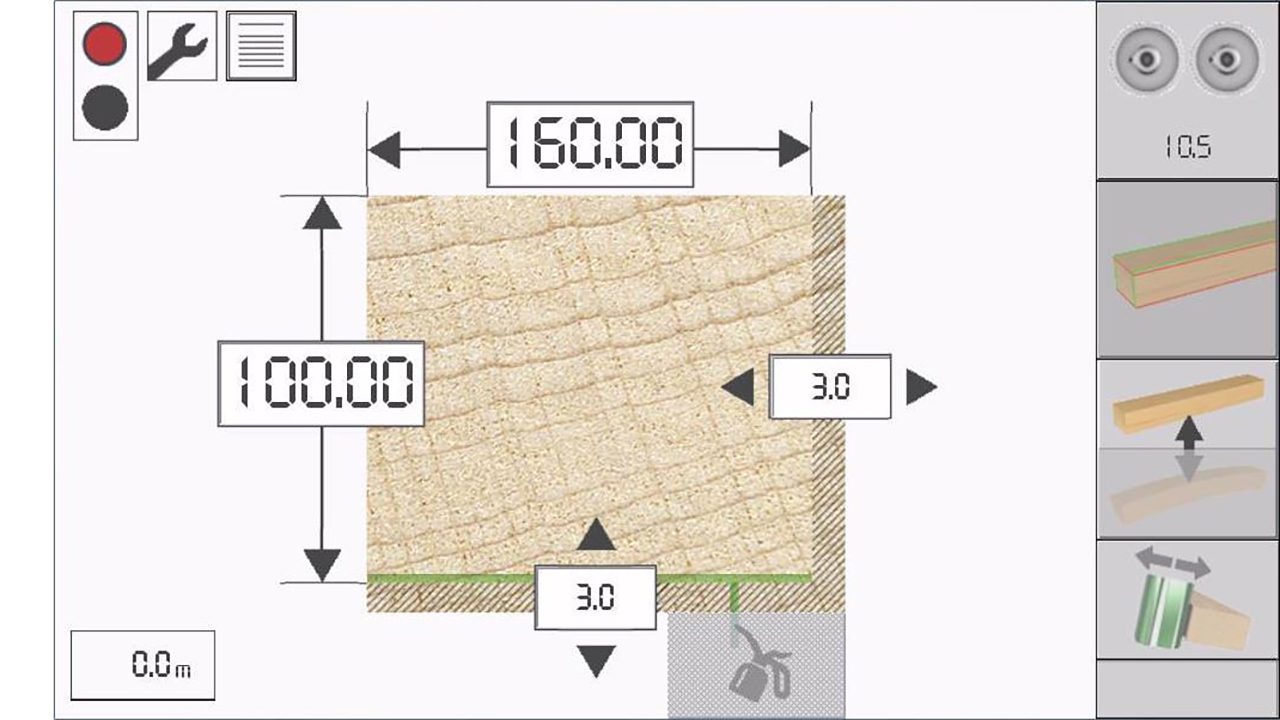

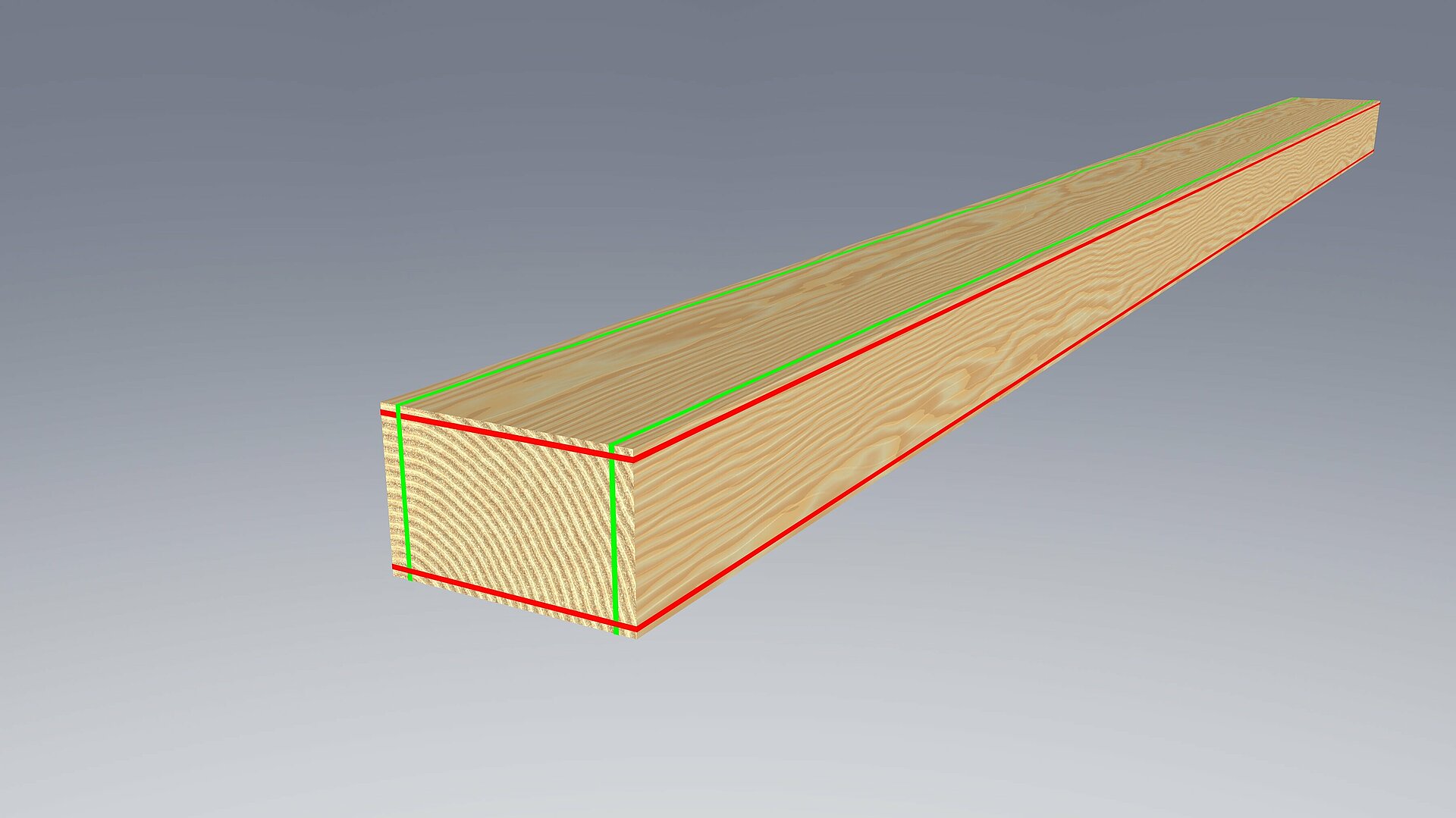

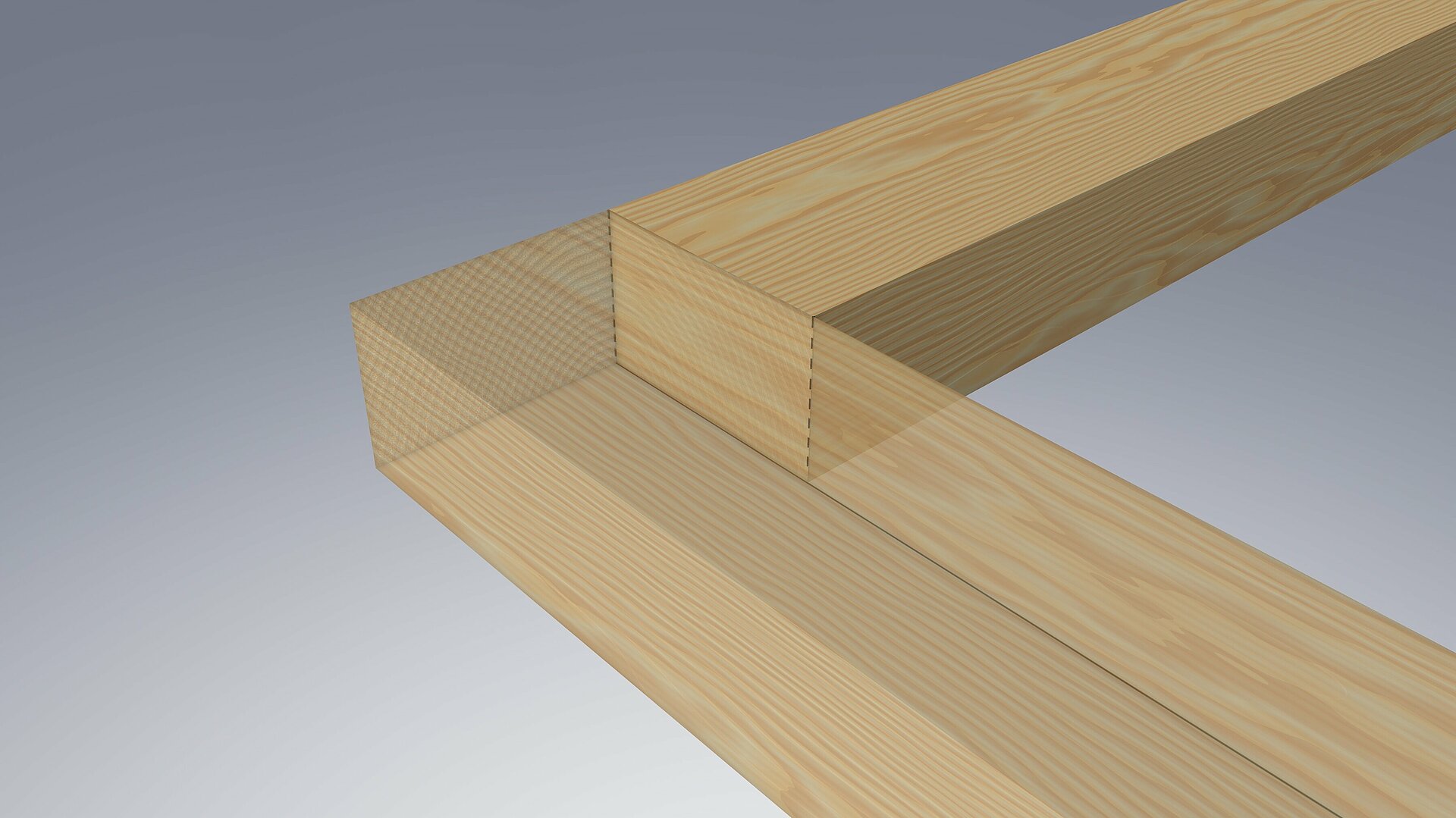

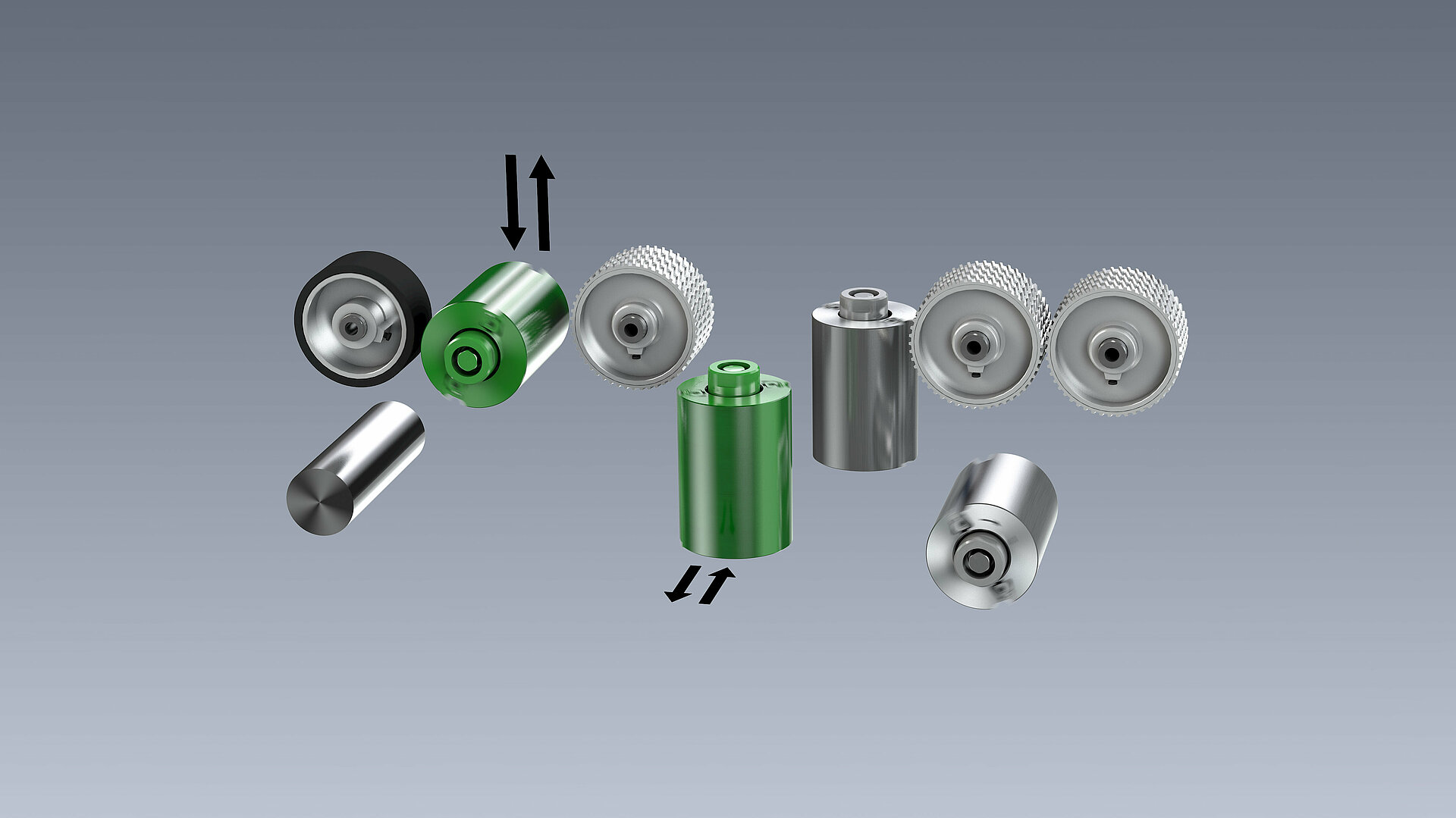

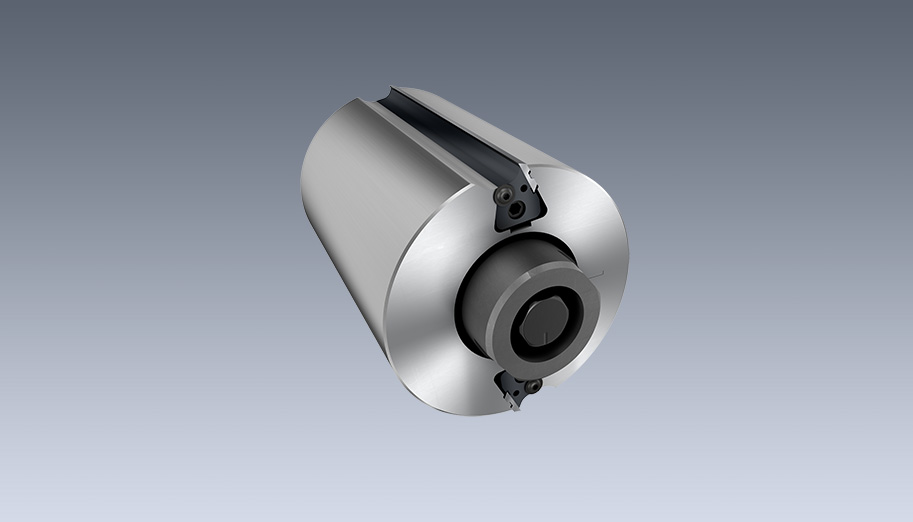

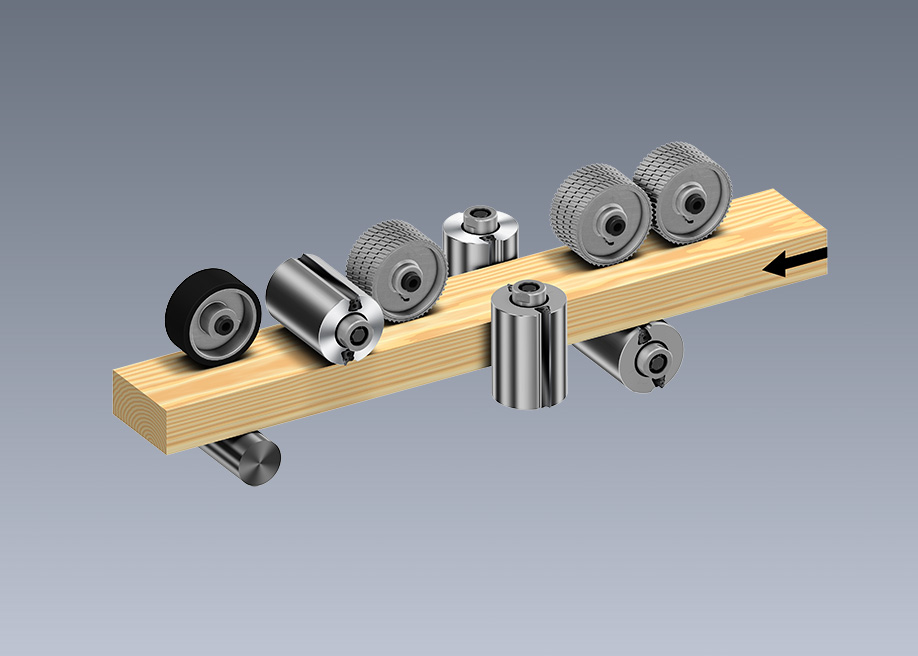

Fast, accurate, efficient. 4-sided planing with no setup. Back to previous pageThe SOLID PLANE CUBE sets new standards in woodworking. It simplifies complex processes, replaces multiple machines and delivers maximum precision and perfect surfaces. Time-consuming work steps and complex set-up are a thing of the past. Dimensional accuracy and rectangularity are achieved in a single, efficient process. Compact in design, powerful in performance and made for maximum productivity.

- Easy to use

- High precision and surface quality

- Fast processing of falling widths

- Requires minimal space

The SOLID PLANE CUBE provides

Versatile solutions for automation

With a modern planing machine, you not only save time in processing, but also in handling the workpieces. This is because there are clever automation solutions at the outfeed table that prevent finished planed parts from falling uncontrollably on the floor. One example of this is the automatic stacker, which picks up the workpieces directly at the machine outfeed and stacks them neatly on top of each other fully automatically.

Want even more convenience? With the T 15 RC return conveyor, the workpieces are automatically returned from the outfeed to the operator at the infeed of the planing machine. This saves you additional trips and increases the efficiency of your production at the same time.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/e/csm_HOLZ-HANDWERK_Header_2026_8801244d4c.jpg)