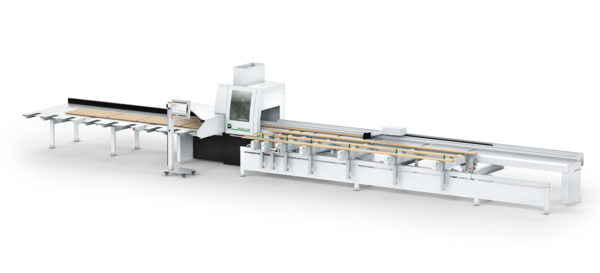

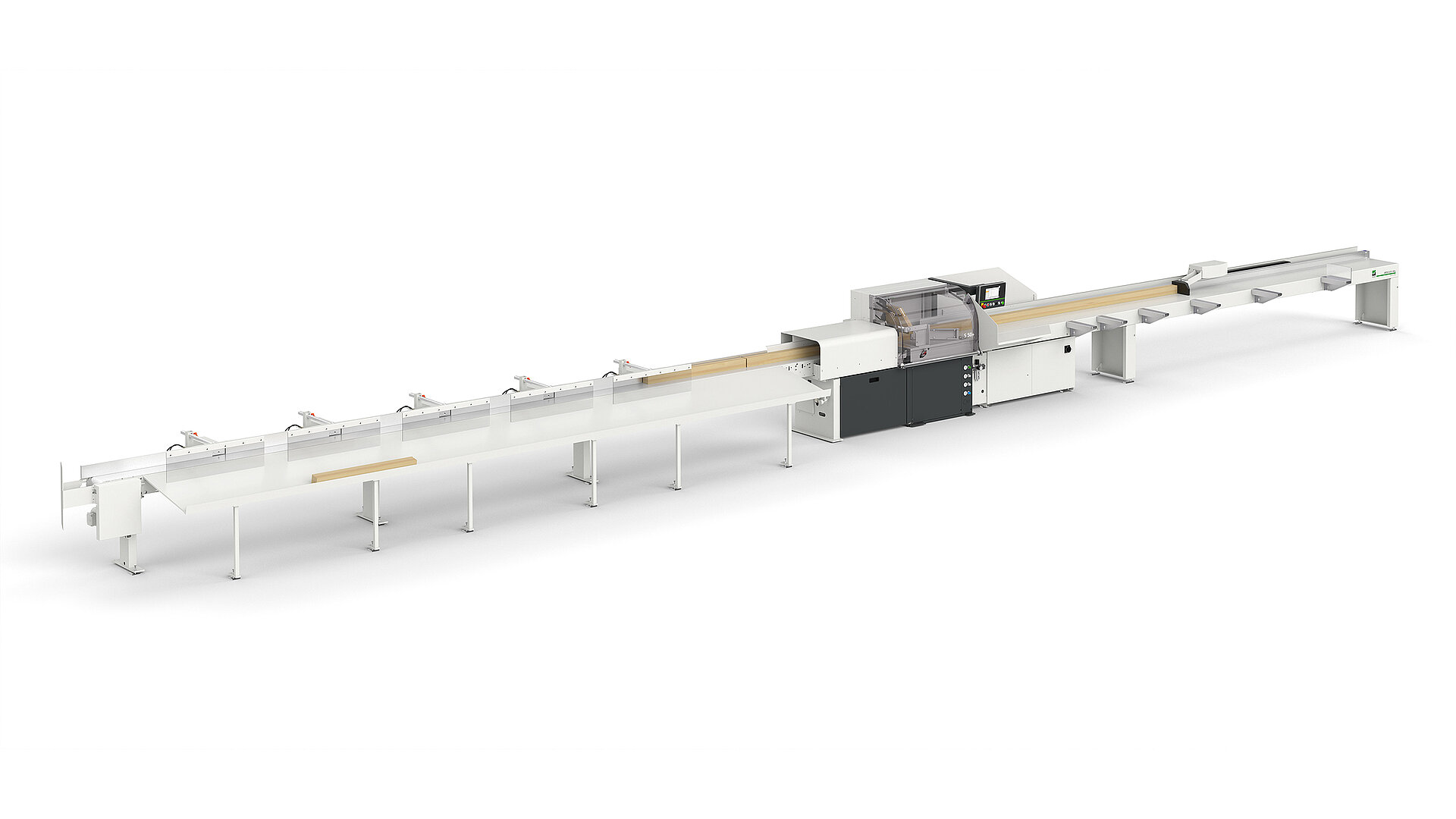

SOLID CUT PF 550 D

Cutting and drilling in a single operation. Back to previous pageThe SOLID CUT PF 550 D drilling unit is the ideal addition for processing workpieces that need to be pre-drilled and cut to length before final assembly. It is particularly suitable for use with mounting and through holes in the range from 4 to 35 mm. This includes, among other things, visible facades and building cladding, terraces or substructures for soft furnishings and urban furniture.

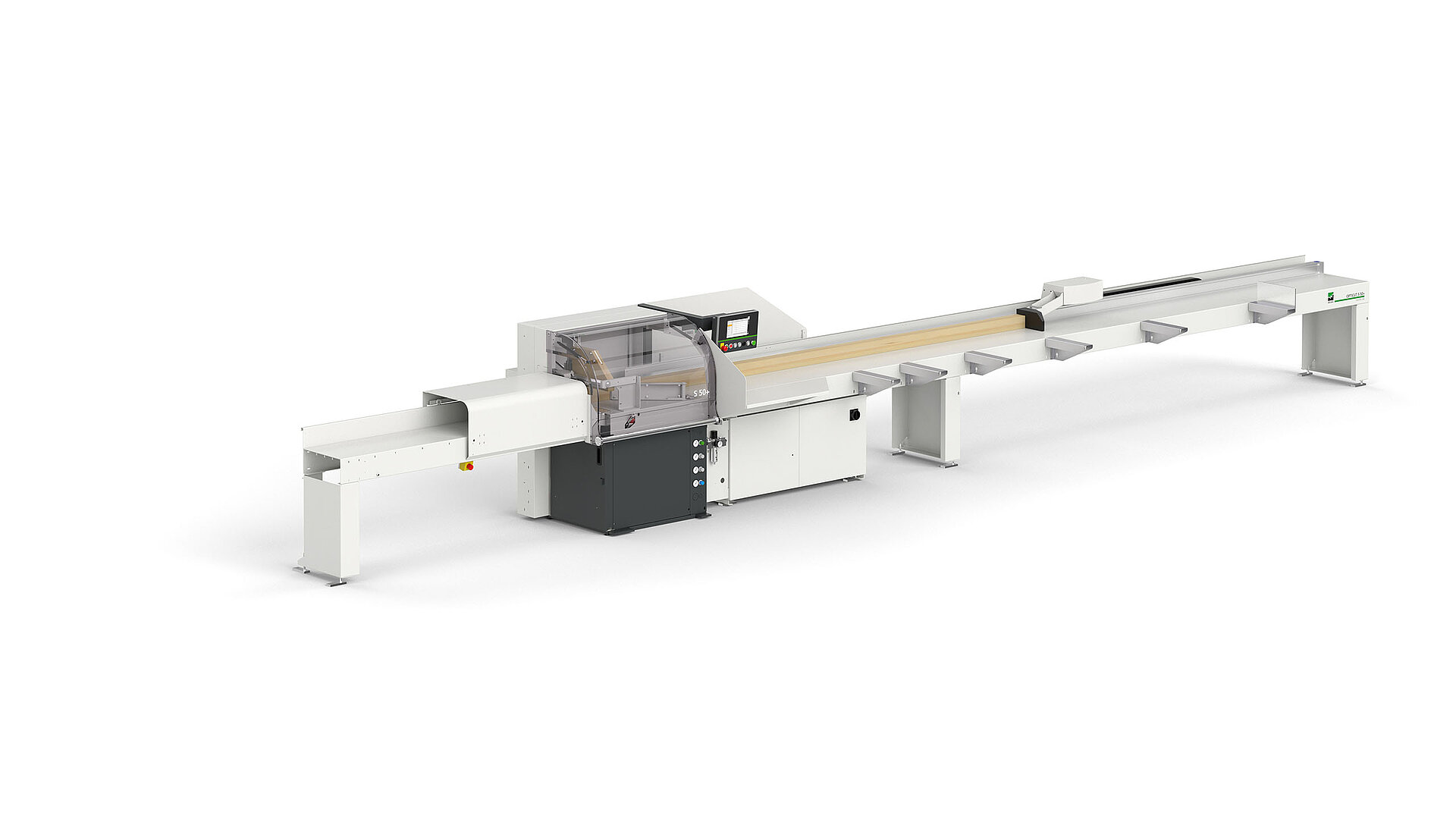

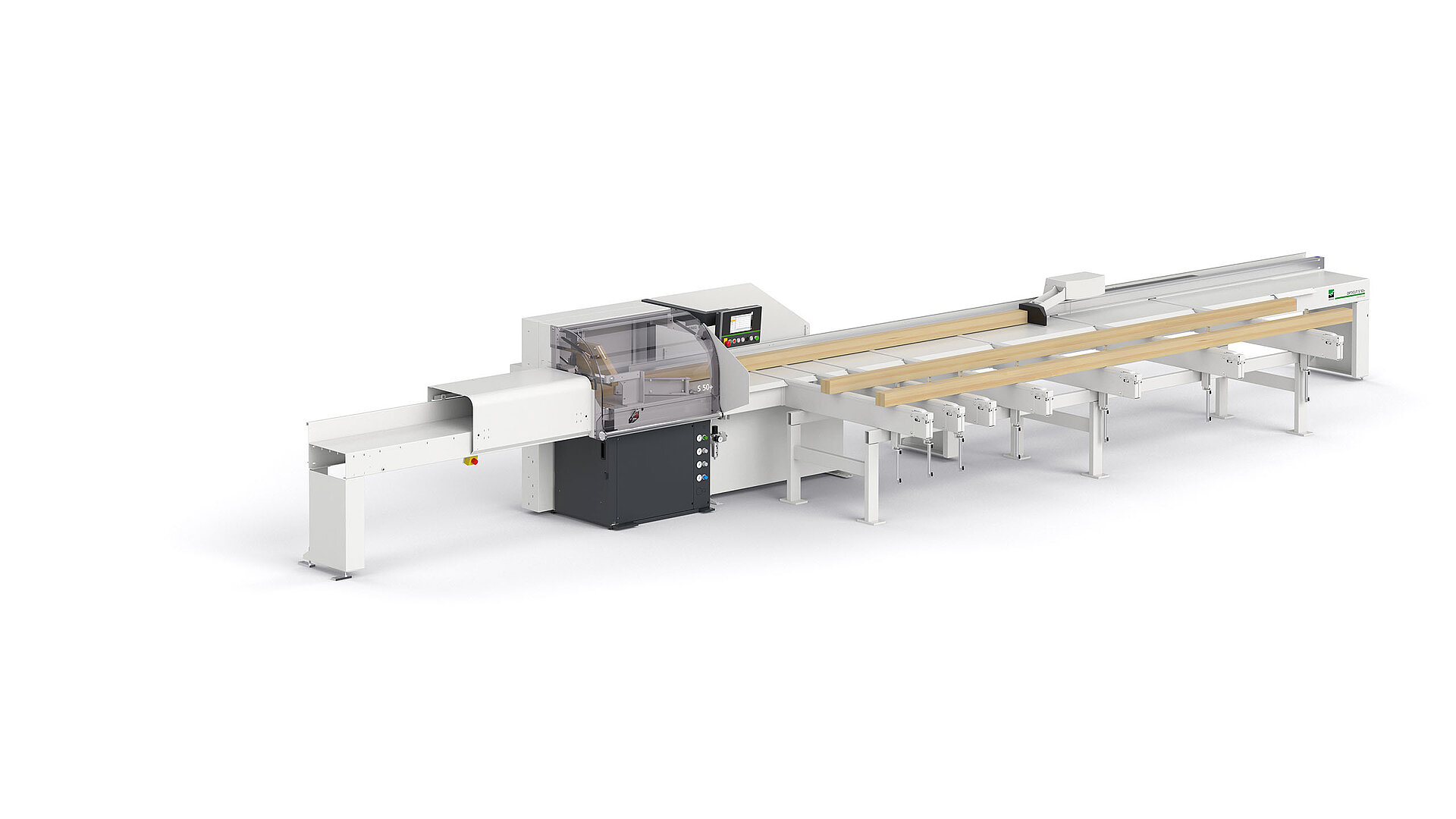

This pushfeed saw is the right choice wherever large quantities of packages or individual boards need to be cut to size. With optimised cutting, you can cut up to four times more than with a manual cross-cut saw. You remain highly productive with maximum yield. Length cutting offers enormous potential for increasing productivity, profit and added value.

In addition to solid wood, many other materials can be cut to size, e.g. plastic, aluminium or wood-based materials, as well as a variety of profile shapes. None of this is a problem for the SOLID CUT PF 550. Even large cross-sectional differences can be handled without major changes to the machine parameters.

- Up to four times the performance compared to a manual cross-cut saw

- Reduced unit costs through single-person operation

- Perfectly retrofittable to create a complete cross-cutting center

- Virtually maintenance-free

- Automatic, intelligent waste disposal

The SOLID CUT PF 550 D provides

In order to master new challenges in wood processing, you need an advanced, efficient and economical production organization. Automated, networked processes are the most important prerequisite for this. A central component is digitization, which ensures extensive exchange of information between man and machine. With the SOLID CUT PF 550, numerous software solutions such as OptiPal, OptiResult and OptiStore can be used for process optimization.

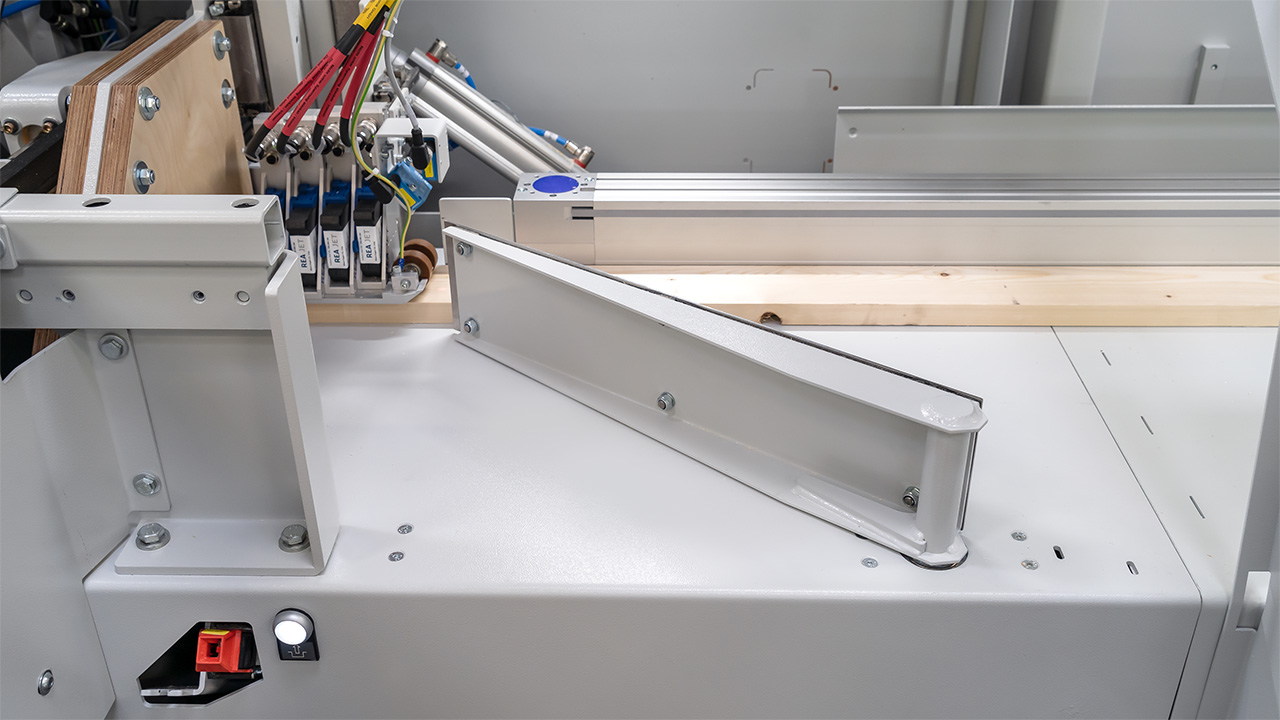

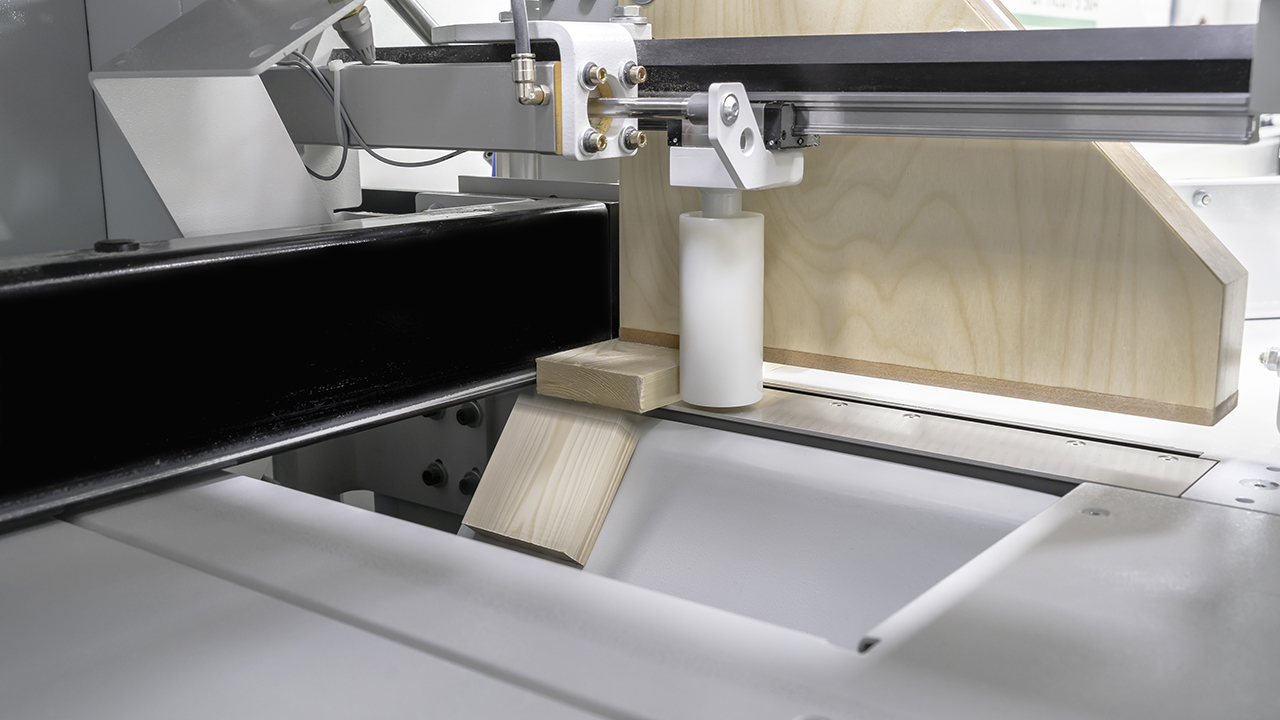

The workpiece clamping system optionally consists of a side guide and pressure roller. The side guide ensures the alignment and pre-clamping of the workpieces, so that a perfect cut can always be made. The swiveling lateral pressure roller in the outfeed presses the workpiece against the fence after the saw blade, ensuring precise right angles even for the last cuts.

SOLID CUT 550 with drilling unit

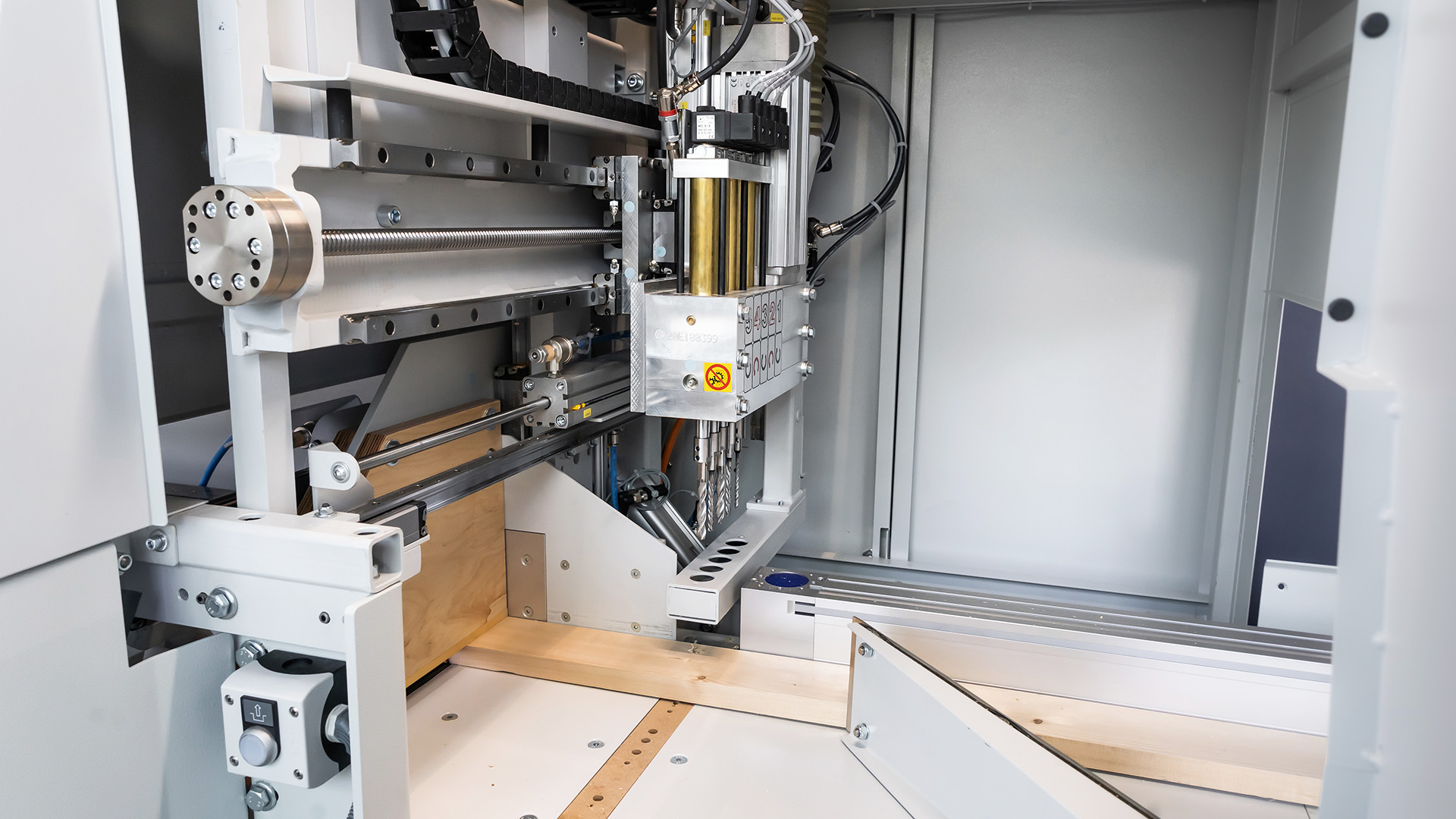

The drillingunit has been specially developed for use with the SOLID CUT 550 D (drilling) optimizing cross-cut saw. Equipped with five drilling spindles, the drilling head allows the use of different drilling tools. The unit can be combined as required with existing options and configurations, such as automatic cross-feeding or sorting. In the machine body, the drilling unit is located upstream of the sawing unit. The unit is designed with high-quality components for precise positioning along the workpiece width (y-axis) and along the workpiece height (z-axis). In the longitudinal direction of the workpiece (x-axis), conveying is carried out with the positioning pusher. A wide variety of pressure options can be used for clamping the workpiece upstream and downstream of the sawing unit.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/e/csm_HOLZ-HANDWERK_Header_2026_8801244d4c.jpg)