![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/e/csm_SOLID_CNC_CR_400_V_911f3ce129.png)

SOLID CNC CR 400 V

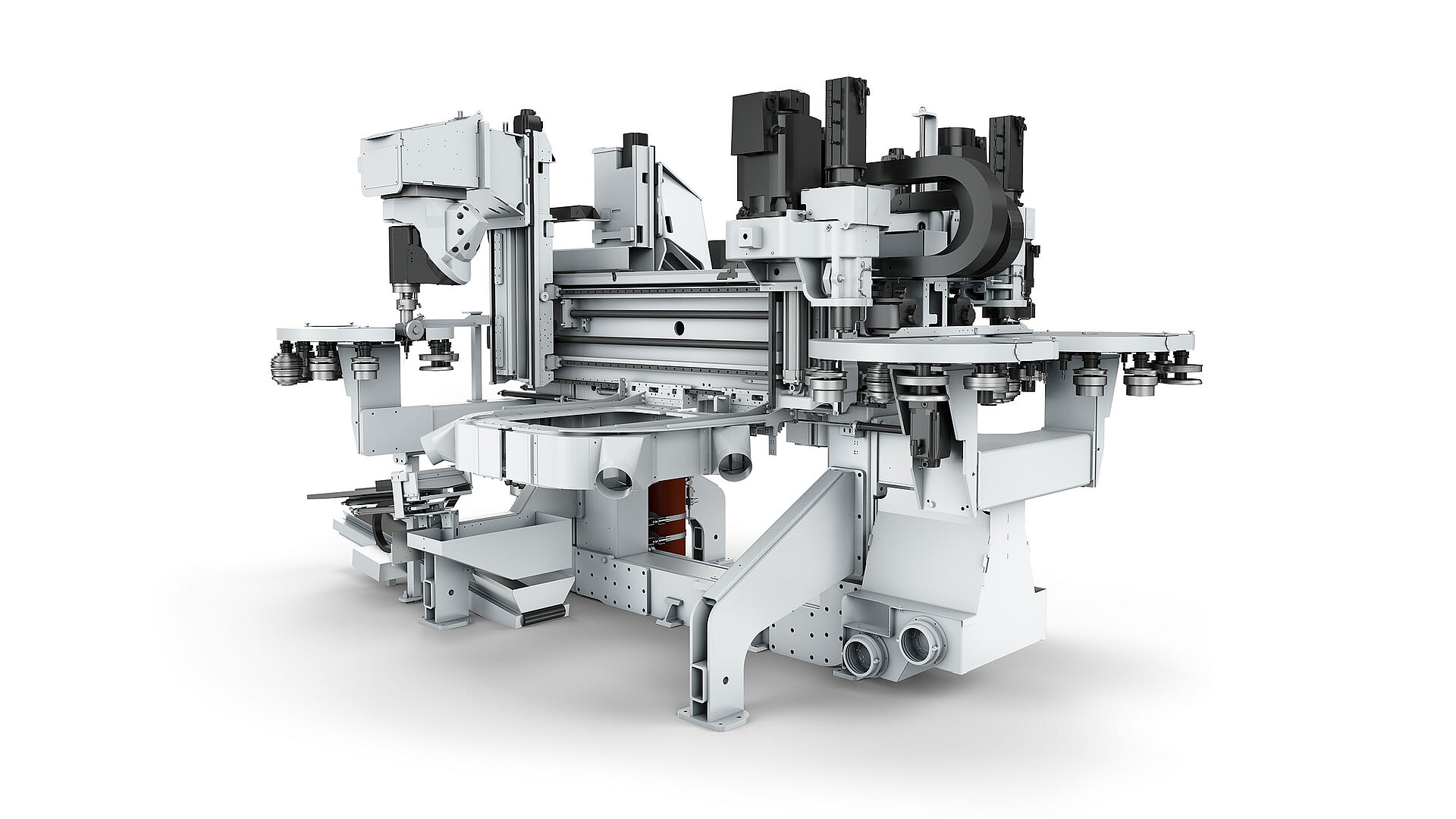

Less space, more flexibility. Back to previous pageThe SOLID CNC CR 400 V offers virtually unlimited machining versatility. From the smallest wooden muntin to large-scale post-and-rail or conservatory elements, everything is possible. The machine represents modern, push-button part production and maximum efficiency in everyday manufacturing. In multi-part mode, it can increase performance by up to 20 percent. Direct, time-neutral part transfer ensures consistently high workpiece quality. Our customers process not only solid wood, modified woods, and wood-based materials but also plastics and composite materials—including aluminum composites. The machine also impresses with maximum productivity, enabling setup-free machining even for the smallest batch sizes.

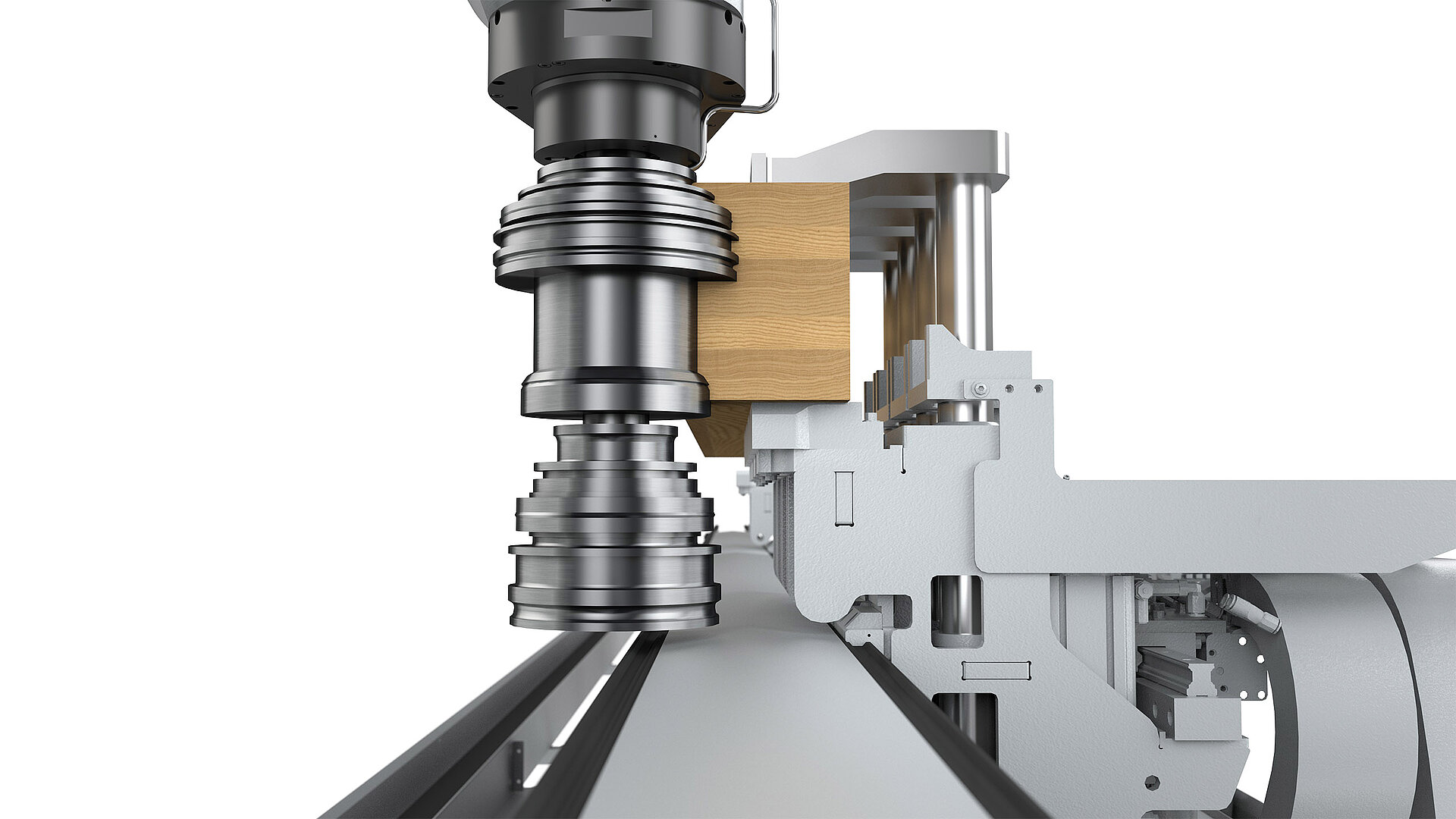

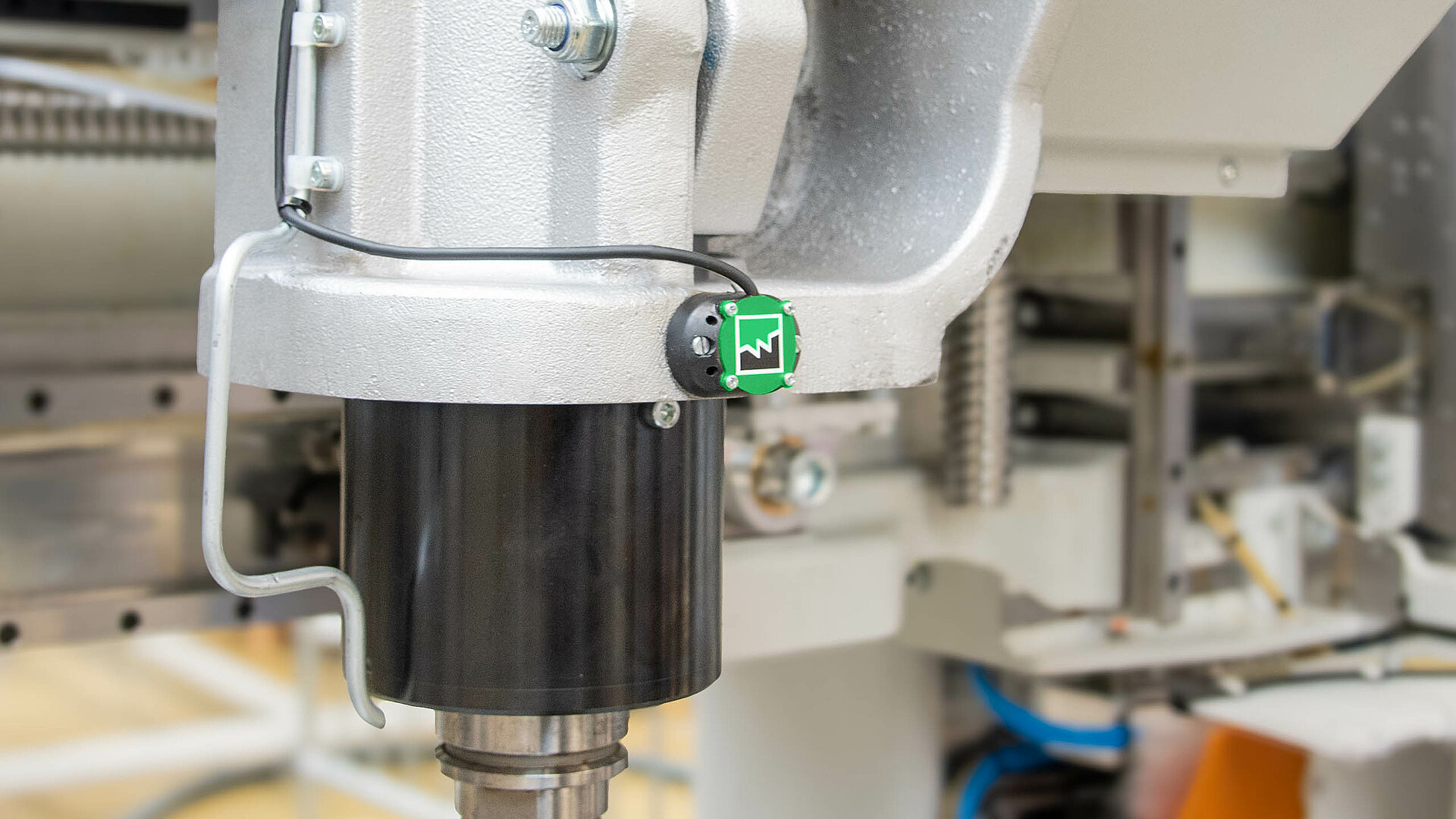

- World's best profiling spindle for solid wood machining

- Intuitive machine operation with WEINIG Machine Control (WMC)

- Sustainable thanks to energy feedback modules and highly efficient drive technology

- Up to 20% performance increase in multi-part mode

- High degree of automation

- Wide range of equipment options

SOLID CNC CR 400 V details*

- Workpiece length min./max.

- 175 mm (clear opening) – 4500 mm

- Workpiece height min./max.

- 25 mm (15*) – 150 mm

- Workpiece width min./max.

- 20 – 330 mm

- Main spindle

- 30 kW

- Universal spindle

- 12 kW

- Tool diameter, main spindle max.

- 340 mm

- Tool length, main spindle max.

- 290 mm

- Internal tool magazine, number of positions

- 24 + 17

- PowerGrip Motion 3D

- X

The SOLID CNC CR 400 V provides

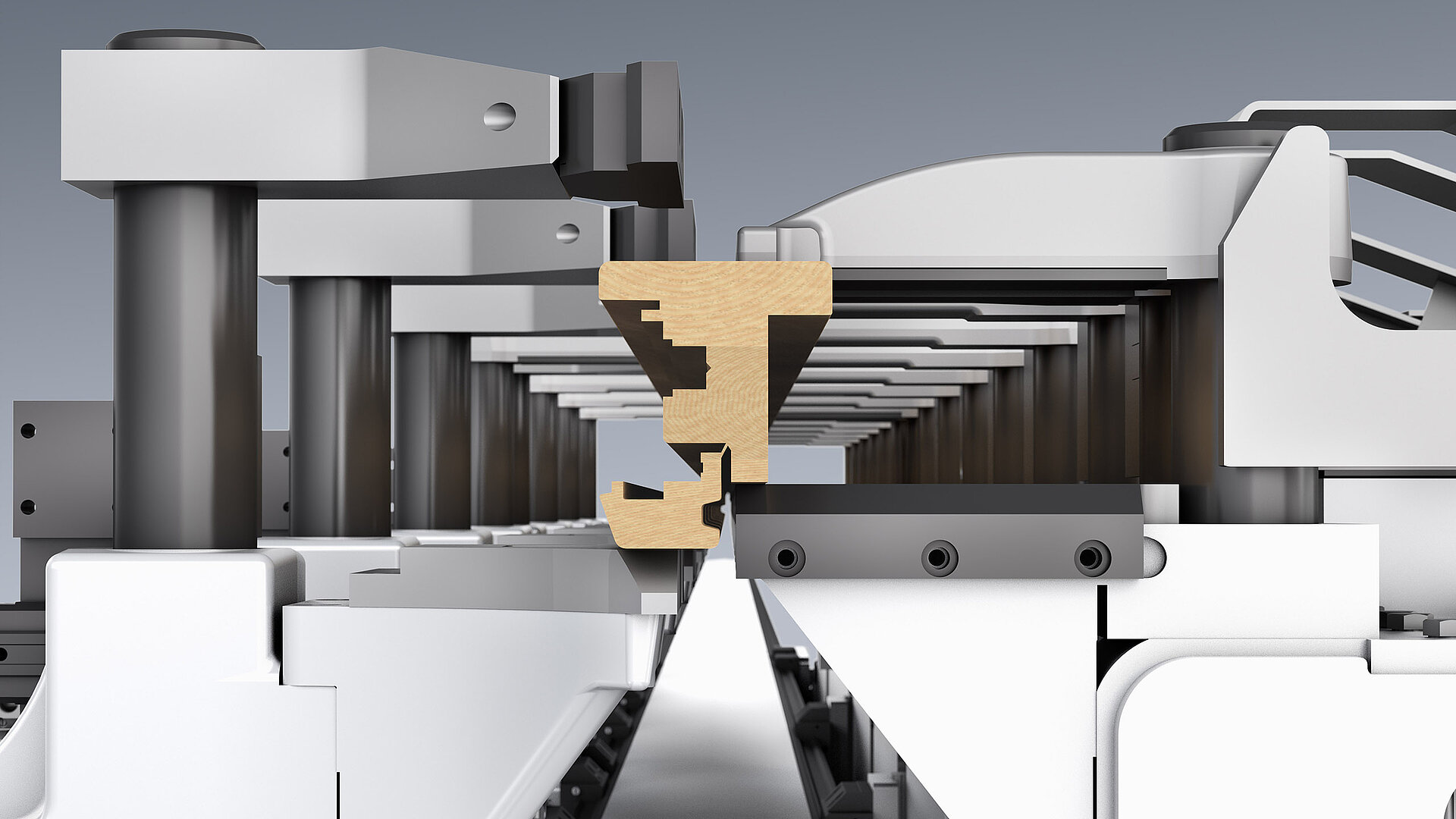

The standard integrated 3D Motion technology opens up entirely new possibilities. Thanks to three-dimensional freedom of movement in the X, Y, and Z axes, new clamping positions can be achieved without any loss of underclearance. This results in significantly greater flexibility while maintaining the same high level of precision during direct part transfer. In addition, workpieces up to 330 mm in width, as well as very small parts, can be securely clamped and precisely machined.

Thanks to its innovative machine cabin, the SOLID CNC CR 400 V is easily accessible for maintenance work. Clear glass panes guarantee optimum visibility into the machine so that you can easily monitor the production process. The CE-compliant fully enclosed machining area ensures the safety of everyone near the machine.

Versatile equipment options

The SOLID CNC CR 400 V offers a wide range of equipment options, allowing it to be perfectly tailored to your specific application and requirements. A universal spindle enables the production of complex window profiles, a 5-axis head provides maximum flexibility across all axes, and multi-spindle drilling heads (MBK) deliver increased performance for horizontal and vertical drilling operations.

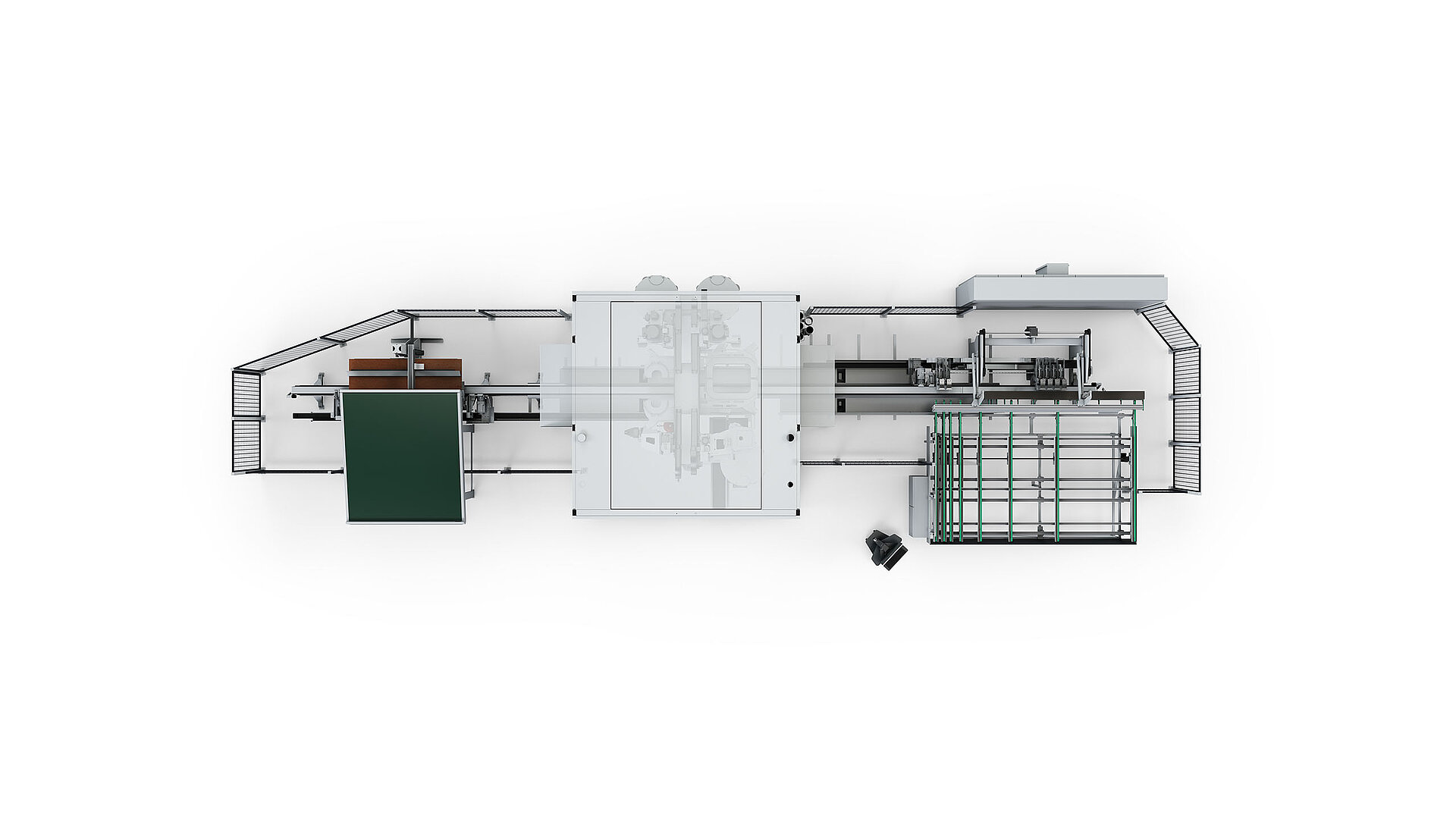

With a broad selection of automation and mechanization solutions, the machine can be seamlessly integrated into your production processes. For example, it can be directly linked to a crosscut-planing or sanding machine. Additionally, the machine’s autonomy can be further increased through trolley loading systems or by expanding buffer capacity.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/e/csm_HOLZ-HANDWERK_Header_2026_8801244d4c.jpg)