![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/7/csm_SOLID_RIP_V_310_M_8e389400b6.png)

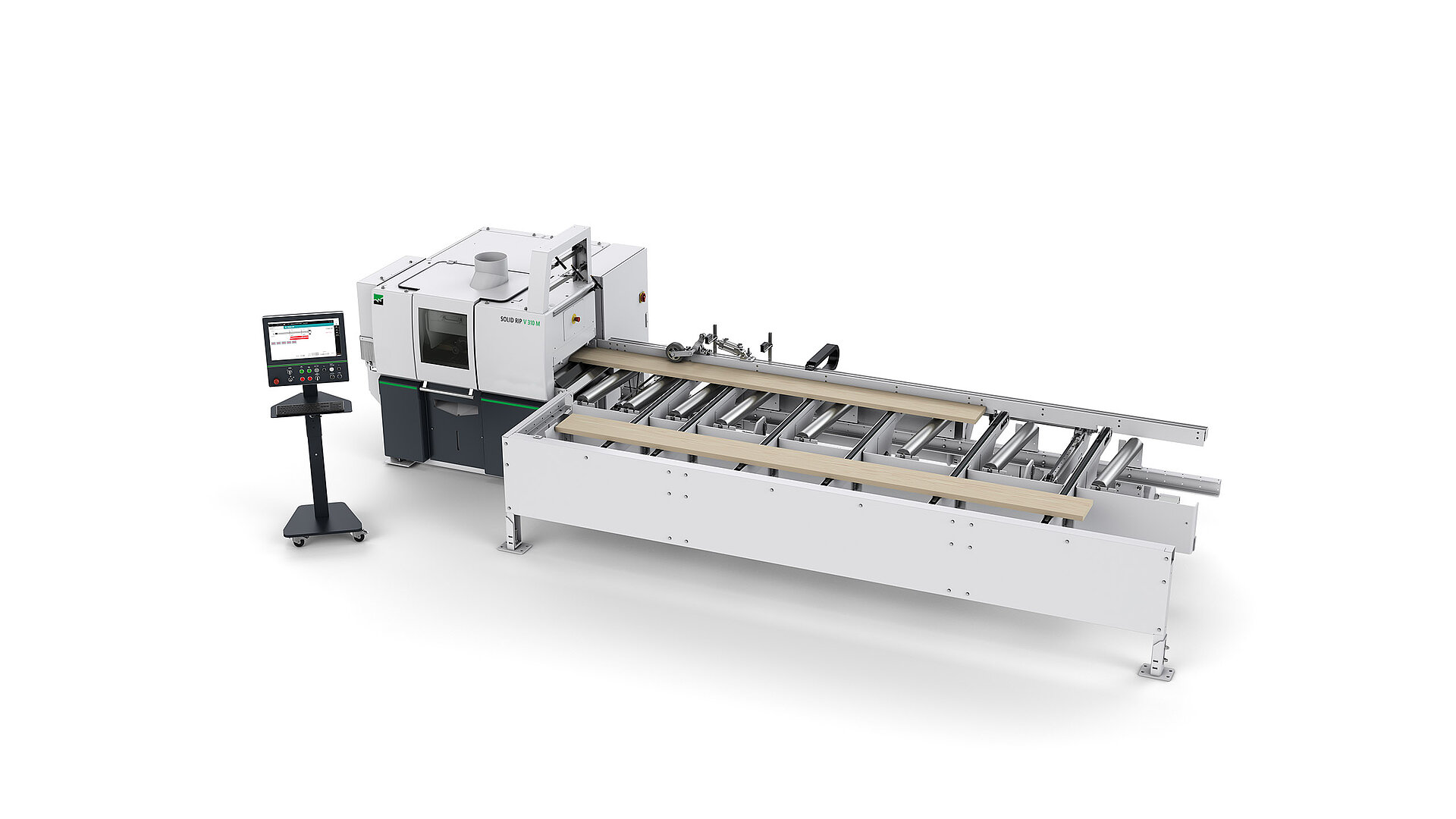

SOLID RIP V 310 M

The intelligent and compact concept for profitable cutting. Back to previous pageThe compact, robust SOLID RIP V 340 M is the ideal machine for small and medium-sized operations. Whether as a multi-blade or optimizing rip saw, the new SOLID RIP V 340 M impresses even in the standard version with high-quality equipment and excellent user-friendliness. The patented Quickfix quick clamping system enables rapid retooling.

SafetyPlus, developed and patented by WEINIG, ensures optimal operator protection.

Upgraded with up to two automatically adjustable saw blades, the SOLID RIP V 310 M offers an intelligent entry into wood optimization. The modular design allows the SOLID RIP V 310 Mto be optimally adapted to every requirement.

- Optimal cutting quality (Glue-joint cut)

- High productivity and economic

efficiency - Wide range of applications (Quick changes between moulding and parts production)

- Maximum operator safety

- Quick saw blade change

- Optimal for integration in system

solutions

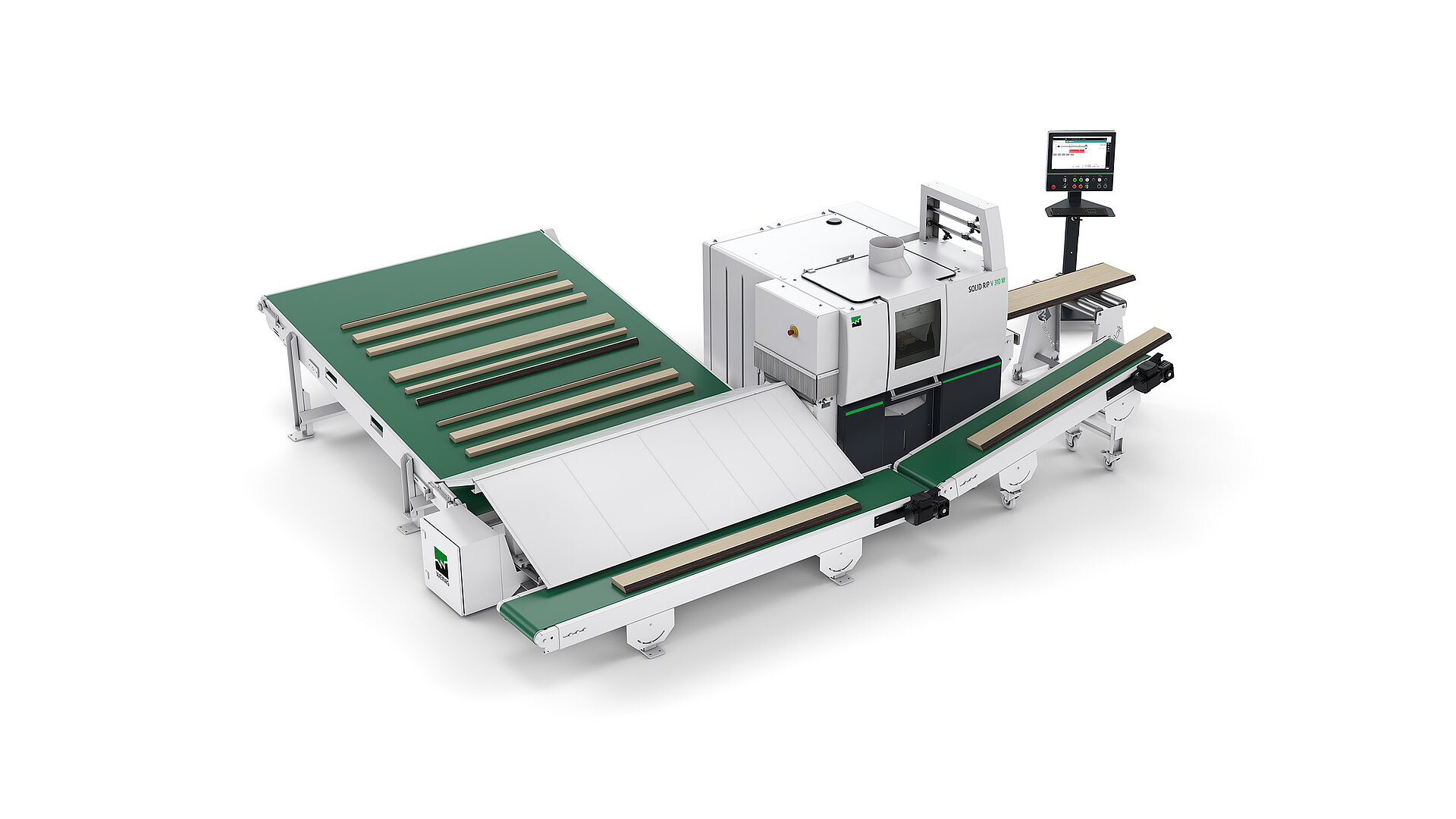

Stand-alone or system solution?

The SOLID RIP V 310 M impresses as an outstanding stand-alone machine and can be seamlessly integrated into versatile system solutions. The individually configurable infeed and outfeed systems can be flexibly adapted to the customer's requirements. The SOLID RIP V 310 M is ideal for processing edged and unedged goods.

The SOLID RIP V 310 M provides

With a conventional fixed arbour setup, varying board widths, qualities and defects lead to material waste in the range of 8% on average. By contrast, the moving blade technology ensures that the raw material is used efficiently. With one or two moveable saw blades you adapt your SOLID RIP V 310 M individually to any board.

You have never before retooled a machine as easily and conveniently as with the patented Quickfix fast release system. Everything is done in the shortest possible time: Release hydraulic tension, insert wood samples. Shift saw blades on the arbour, apply hydraulic tension. Done. With out any bushings, spacers or tools.

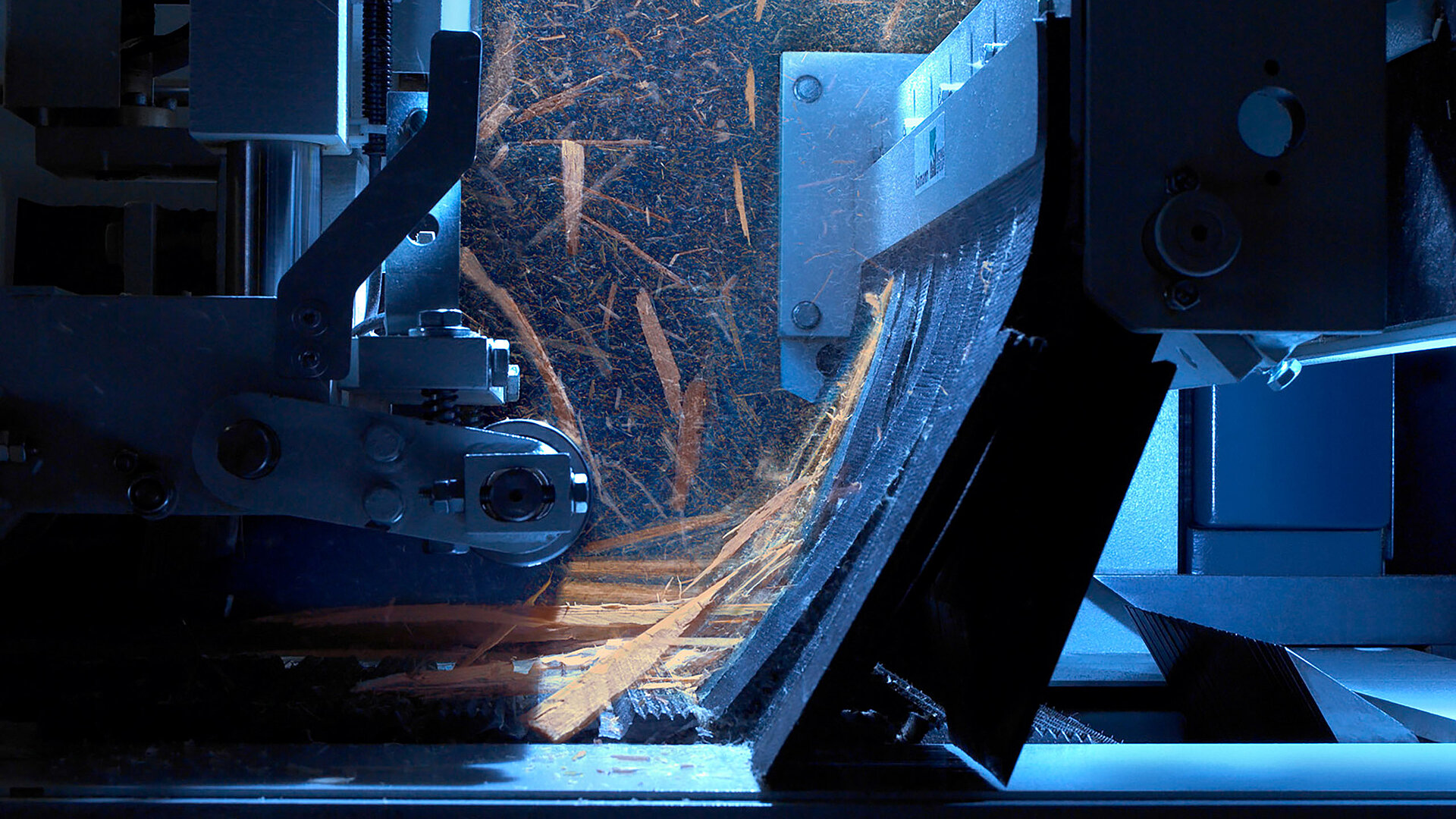

With the new, patented SafetyPlus, Raimann offers even better protection for the operator. SafetyPlus is a multi-layer curtain made of Kevlar fabric and a layer of polyurethane that enhances the existing range of splinter traps. The Kevlar fabric, known from its use in bulletproof vests, lies on the feed chain and thus closes the gap between the chain and the splinter trap, which was previously caused by the design. By sealing the cutting area in this way, splinters are reliably held in the machine. The operator is optimally protected.

RipAssist width optimisation

RipAssist automatically calculates the optimal ripping solution for each board and positions the movable saw blades accordingly. The operator checks the result via the laser lines on the board and can correct the solution by means of the joystick or touch screen, if necessary.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/d/csm_Header_Holz-Handwerk_2023_a6ad700671.jpg)