![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/a/csm_SOLID_PROFILE_P_500_a859b40322.png)

SOLID PROFILE P 500

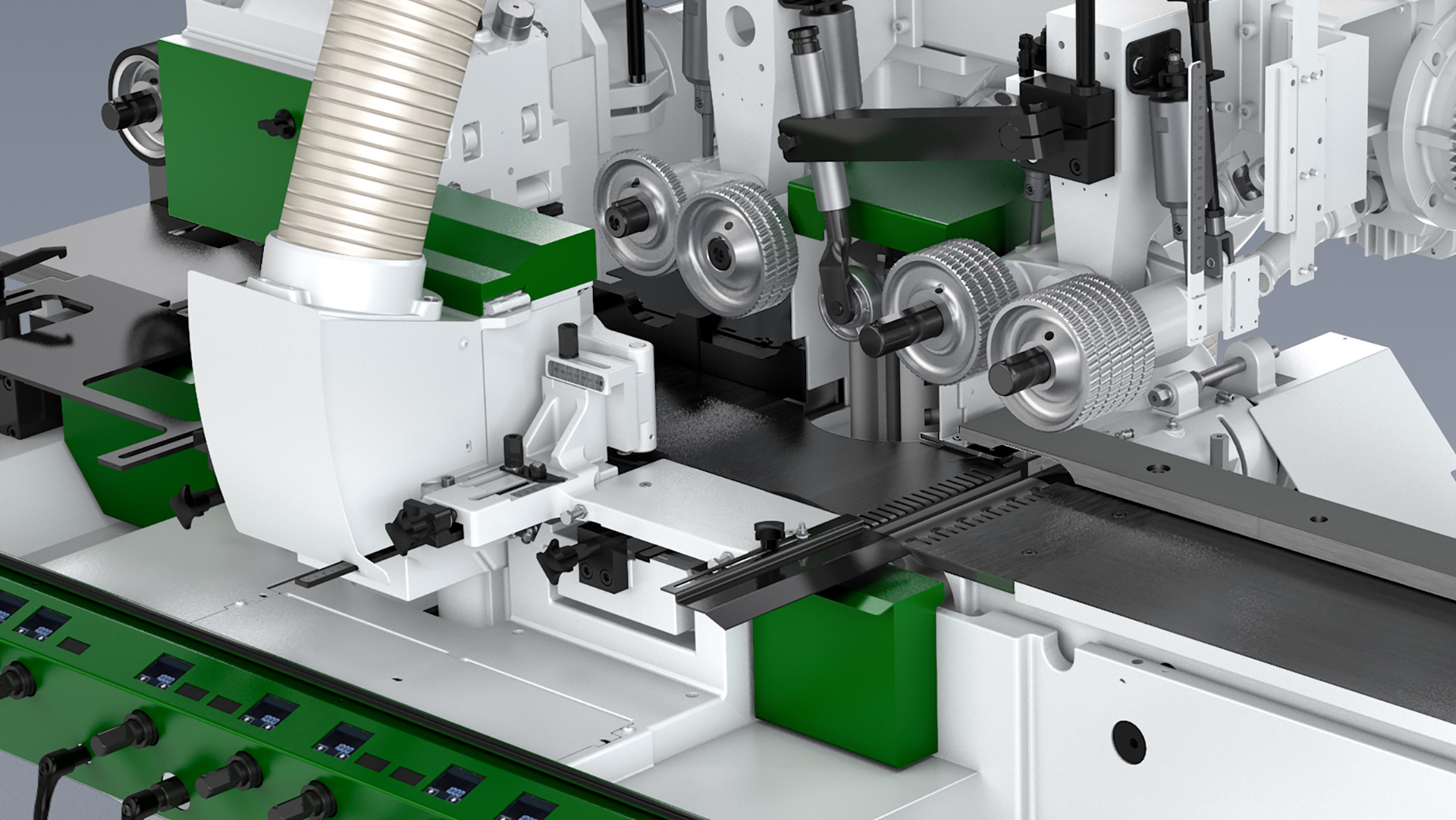

Reliable, fast & flexible Back to previous pageWhen a company sets out to find a suitable successor, important questions arise: What does the next generation have to do to meet the increasing challenges of a rapidly changing industry? Who offers the speed, flexibility, reliability and quality needed to survive in the market in the long run? The WEINIGSOLID PROFILE P 500 is the answer to these questions.

- Robust and low-maintenance design for a long lifetime

- Machine configuration can be individually configured

- Easy to operate - with or without the support of a machine control system

- Short set-up times and high user safety

- Variable working width of up to 260 mm

The SOLID PROFILE P 500 provides

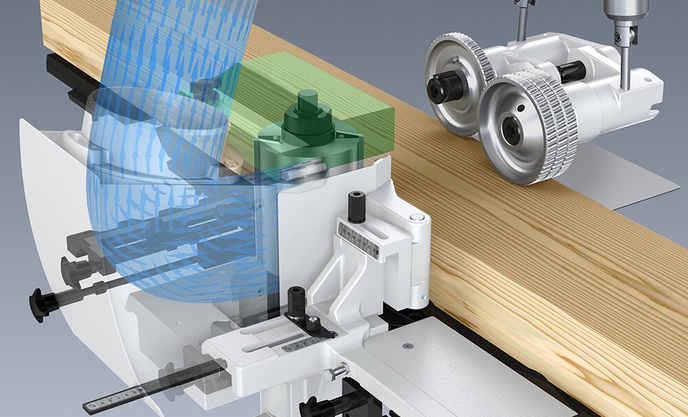

On request, the SOLID PROFILE P 500 can be equipped with an intelligent control package for reproducible results at the push of a button – including a 10.1” display with intuitive user guidance. The width and thickness are automatically set to a nominal dimension. Alternatively the machine can be adjusted manually.

The Profimat moulding machine in use

Das Holzwerk Weiss stellt Leisten, Kanteln, Bretter und Fassaden für die Region her. Vor zwei Jahren hat sich das das Unternehmen einen Profimat 50 in breiter Ausführung in die Produktion geholt. Warum der Profimat 50 so flexibel ist und bis heute begeistert, erfahren Sie imVideo.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/d/csm_Header_Holz-Handwerk_2023_a6ad700671.jpg)