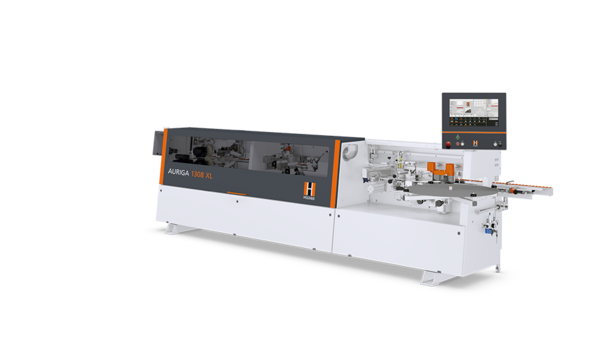

AURIGA 1308 XL

Fully automatic edgebanding machine with motorized adjustment – the benchmark for the modern carpenter. Back to previous pagePerfect edge finish is achieved on HOLZ-HER AURIGA edgebanding machines thanks to the Glu Jet adhesive application system. This unique hybrid technology ensures a harmonious interaction between adhesive, edge, and panel material. The Glu Jet system allows effortless use of either EVA or PUR adhesives, available as cartridges or granules, and is highly energy-efficient thanks to a short heat-up time of just 3 minutes and low energy consumption during adhesive re-melting.

Maximum automation in its class – with three finishing units in the AURIGA series. This eliminates any need for manual rework. All setup operations are performed via modern servo axes without opening the machine hood. In its class, the AURIGA edgebanding machine impresses with above-average productivity and top-of-the-line equipment, setting the standard for the modern carpenter.

Auriga 1308 XL details

- Total length

- 4,930 mm

- Total weight

- 1,400 kg

- Feed rate

- 10 m/min* (with corner copying: 10 m/min)

- Processing units

- 11

- NC servo axes

- 15

- Operation

- 21.5” touch control panel

- Edge thickness

- 0.4 – 8 mm

- Minimum workpiece width

- 60 mm

- Minimum workpiece length

- 160 mm

- Workpiece height

- 8 – 60 mm

- Adhesive type

- PUR / EVA

The Auriga 1308 XL provides

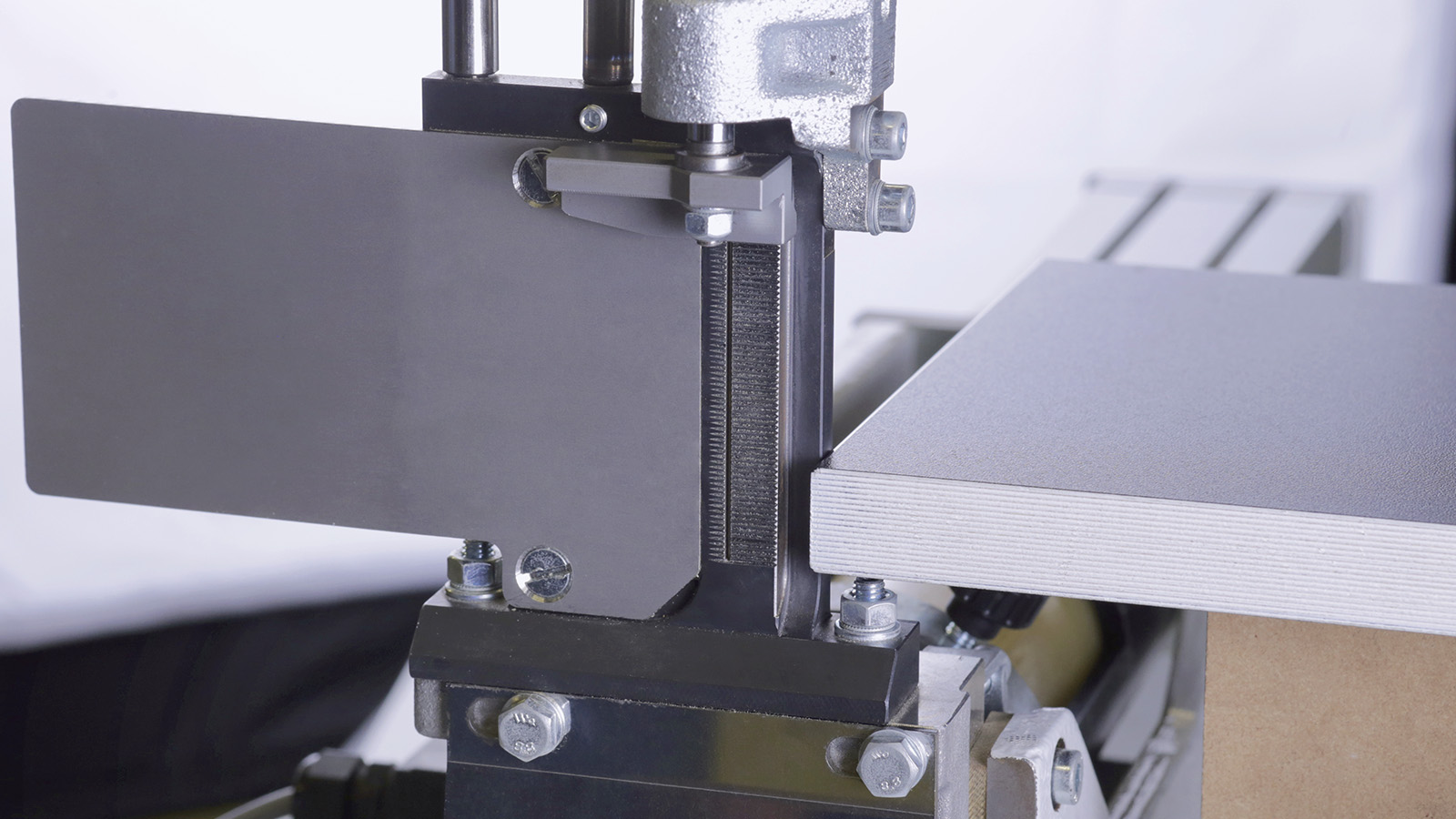

The trend toward seamless edges in industry and craftsmanship is unstoppable, and everyone wants the sophisticated “one-piece” look. All HOLZ-HER edgebanding machines enable optical zero-joint edges using PUR adhesive. With the Glu Jet adhesive application system, you achieve strong, waterproof, and heat-resistant bonds – quickly, cleanly, and reliably in a seamless finish. Perfect for carpenters and furniture makers who demand precision and efficiency in edgebanding.

You can always see graphically which corrections are being made and in which direction. The values entered on the control panel are automatically converted in the background to the actual axis values.

- Easy visual identification of correction settings through intelligent graphics

- Effortless axis adjustment in 0.01 mm increments

- Ideal for material with protective film

- Compensation for edge tolerances

- No need for test workpieces

Your intelligent edge assistant

At the push of a button, the gluing station is perfectly clean. Always know how much is left thanks to residual adhesive quantity monitoring. Whether thin edging or thick veneer edging – the impact shears adaptively apply exactly the right amount of power. Solid wood or thin edging – the pressure unit always uses the optimal pressure combination.

- Adaptive trimming knife

- Automatic adhesive quantity control

- Automatic flushing routine

- Automatic pressure unit

- Residual adhesive quantity monitoring

Efficient edgebanding through “set-up in the gap”. With fa.s.t., different processing operations can be run simultaneously within the edge banding machine, ensuring full utilization of all capacities.

By selecting programs from the program memory, the units are automatically adjusted. This allows multiple processing operations to be carried out at the same time, eliminating idle runs of the edgebanding machine.